To ensure the optimal performance of robots in carrying out their tasks, businesses need to prioritize regular care, maintenance, and continuous improvement. This practice not only ensures efficiency and productivity but also helps save costs in the long run.

The role of maintenance and improvement in robotics is crucial for ensuring optimal performance and efficiency. While robots can operate continuously without the need for extensive breaks like humans, regular inspections and maintenance are necessary to detect any signs of abnormalities. In factory production lines where robots and machinery operate as a system, a single faulty component or device can cause a complete halt in operations. Therefore, preventive measures or early detection through regular maintenance are essential to ensure uninterrupted production.

Many businesses may question the need for maintenance, considering it an unnecessary expense when the machines are functioning well. However, the reality is that neglecting regular robot maintenance can lead to costly repairs when breakdowns occur. The expenses incurred in such cases are higher than the cost of regular maintenance.

Maintenance also extends the lifespan of robots by reducing and slowing down the wear and tear process, especially in unseen electronic components.

Robot improvement is also an avenue that businesses should explore and implement. With the rapid development of Industry 4.0 technologies and advancements, upgrading the equipment becomes necessary to enhance efficiency and overcome existing limitations. Robots can be improved by replacing certain parts, adding new functionalities, increasing speed, or eliminating unnecessary features.

By prioritizing maintenance and continuous improvement, businesses can maximize the performance, longevity, and cost-effectiveness of their robotic systems, ensuring smooth operations and staying competitive in the evolving technological landscape.

Some notices when maintain and improve robot

When applying robots, it is important to refer to and understand the maintenance recommendations provided by the supplier. Each type of robot has different maintenance intervals. Additionally, the maintenance activities depend on factors such as the working environment, climate, and operational procedures of the system.

Since robots involve technology and engineering, they should be maintained and upgraded by skilled professionals, engineers, or experienced technicians who have knowledge of machinery. Proper skills, experience, and correct procedures will save time and accurately assess the condition of the robot and address any issues to ensure optimal performance of the equipment.

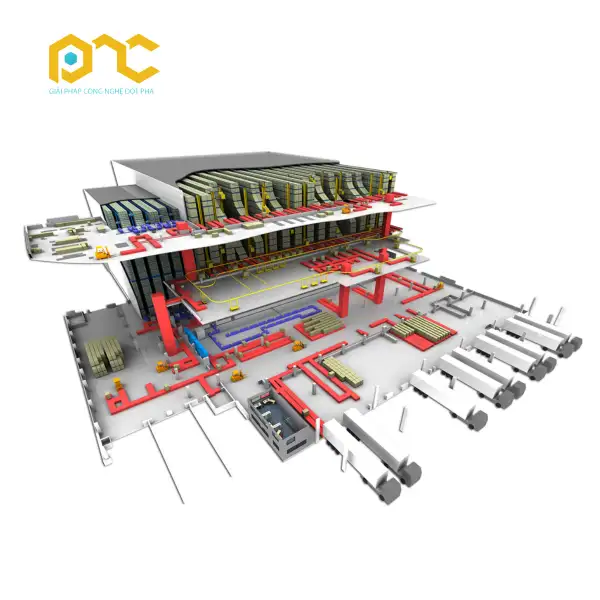

Service of PNC TECH

PNC Tech provides comprehensive maintenance and improvement services for robots, backed by a team of professional engineers with over 10 years of experience in robotics. The services are implemented in an optimized and efficient manner.

Preventive Maintenance: PNC Tech’s dedicated Preventive Planned Maintenance (PPM) team carries out scheduled maintenance to proactively prevent robot breakdowns. During regular maintenance visits, the team performs routine maintenance activities such as lubrication of mechanical components, battery checks, software backups, and replacement of predetermined parts.

Robot Health Check: PNC Tech conducts thorough health checks for customers who purchase used or refurbished robots to identify any underlying issues. Engineers perform a visual inspection of 60 points on the robot and its control system, providing reports on their findings and recommendations.

Robot Improvement and Refurbishment: PNC Tech offers refurbishment or repair services for robots at their workshop, extending the lifespan of the equipment. This helps businesses save costs compared to purchasing new robots.

If your business is in need of robot maintenance and improvement to enhance efficiency and cost savings, contact PNC Tech today for detailed consultation.

PNC Tech Automation Company Limited

Hotline: 0919 247 843

Email: diep.ns@pnctech.vn

Address: Building A17, 17 Ta Quang Buu, Hai Ba Trung, Hanoi.