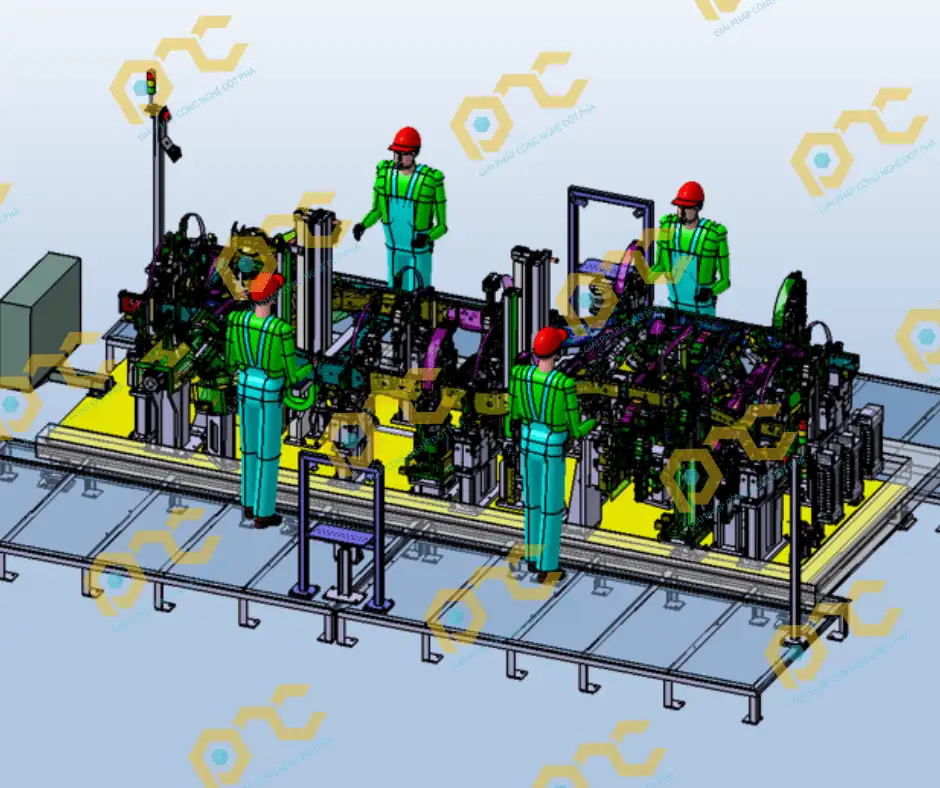

In industrial manufacturing, welding jigs play a vital role in ensuring precision, stability, and optimized productivity. Recently, PNC TECH successfully completed a special project – the design and fabrication of welding jigs for Nissan’s production line, serving as clear evidence of the company’s capability to meet some of the world’s most stringent technical standards.

Nissan’s Strict Requirements

Working with Japanese enterprises – especially leading corporations like Nissan – means that products are not only required to meet specifications but must also pass through a series of rigorous technical standards. Among them, two core factors that Nissan consistently prioritizes are 5S and JIS.

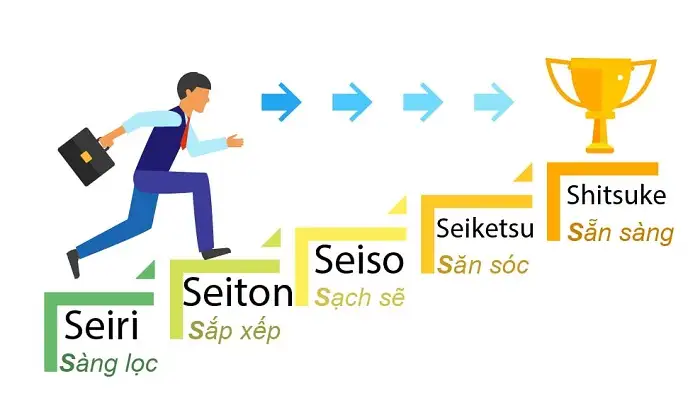

5S – The Japanese Philosophy of Management and Production Process Improvement

5S is considered the “cultural foundation of manufacturing” in Japan. More than just an operational principle, it is a philosophy that optimizes productivity, ensures quality, and builds a disciplined, organized, and efficient workplace.

Specifically, 5S consists of:

- Seiri (整理) – Sort: Remove unnecessary tools, equipment, and materials from the workspace to minimize waste of space and searching time.

- Seiton (整頓) – Set in Order: Arrange tools and materials in a systematic way for quick access and usage.

- Seiso (清掃) – Shine: Keep the workplace clean to prevent dust and dirt from affecting product quality.

- Seiketsu (清潔) – Standardize: Maintain and standardize established cleaning and organizing practices.

- Shitsuke (躾) – Sustain/Discipline: Foster habits of compliance, discipline, and professional working behavior.

Special Note: For Nissan, 5S is not just an internal process but also a key criterion in evaluating supplier capability. A product manufactured in a 5S-compliant environment is almost guaranteed to deliver long-term stability and quality.

For this project, Nissan required welding jigs to be machined with extremely low tolerances, operate stably 24/7, and allow easy maintenance and part replacement when necessary.

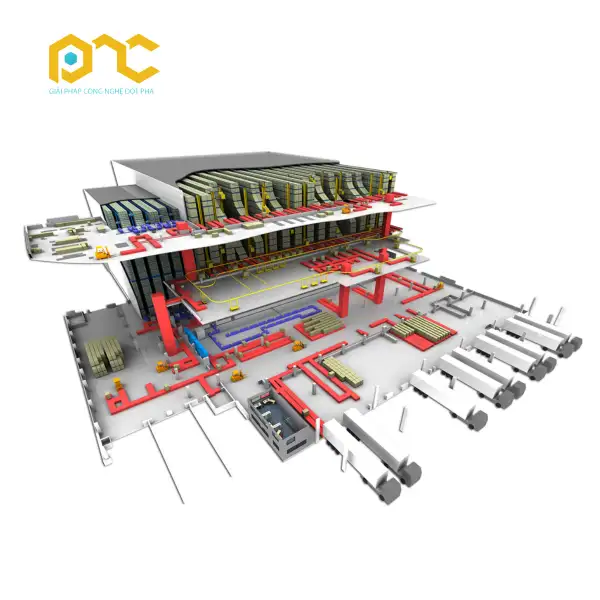

PNC TECH’s Execution Process – From Concept to Handover

The project was carried out in three main phases:

1. Research & Design

- Direct communication with Nissan engineers in bilingual Vietnamese–Japanese: PNC TECH ensured that all technical requirements, operational steps, and quality standards were accurately understood.

- Production line and condition analysis: The engineering team studied equipment layout, operator workflow, and working environment to guarantee efficiency and safety.

- 3D design with professional CAD software: Every component was simulated with minimal deviation, ensuring jig precision and worker-friendly operation.

- Technical documentation standardized in Japanese: Including drawings, specifications, operating manuals, and testing data, facilitating smooth acceptance and usage in Japan.

2. Manufacturing & Quality Control

- JIS-compliant material selection: All materials underwent strict quality inspections before machining.

- High-precision CNC machining: Multi-axis CNC machines at PNC TECH’s facility ensured the lowest possible component tolerances.

- Trial assembly and operation checks: Each jig was assembled and tested to evaluate alignment, clamping force, and stability.

- Rigorous inspection of every detail: Dimension checks, load testing, surface durability assessment, and full-system operational trials.

3. Installation & Handover

- PNC TECH engineers traveled directly to Nissan’s plant for installation and fine-tuning.

- The product passed all tests and was officially put into operation.

(Learn more about PNC Tech’s article on Welding Jig Solutions)

Results & Delivered Value

- Boosted productivity: Reduced welding operation time and increased line efficiency.

- Absolute reliability: Stable operation, long lifespan, and reduced maintenance costs.

- International recognition: Project success strengthened PNC TECH’s reputation in the Japanese market and opened doors for new collaborations.

Key Lessons from Working with Japanese Partners

Through this project, PNC TECH derived three golden principles:

- Strict compliance with technical standards (5S, JIS).

- Transparent and detailed communication aligned with Japanese business culture.

- Tight quality control from design through to delivery.

PNC TECH is ready to accompany Japanese and global enterprises in delivering jigs, fixtures, and automation solutions that meet international standards. With proven experience at Nissan, we are confident in providing high-quality, efficient, and sustainable products.

Learn more about our services:

📞 Hotline: (+84) 919 247 843

✉️ Email: sales@pnctech.vn

🔗 LinkedIn: pnctech.vn