In the era of Industry 4.0, quality control and continuous operations are critical for manufacturing survival. Two breakthrough technologies—Machine Vision and the Internet of Things (IoT)—are considered the “eyes” and “lungs” of automation. Together, they help businesses achieve precision manufacturing while optimizing operational efficiency.

In Vietnam, PNC TECH is among the pioneers in deploying these solutions, delivering tangible value to automotive, electronics, logistics, and smart warehouse industries.

Machine Vision – The “Eyes” of Automated Production

Machine Vision leverages industrial cameras and image processing algorithms to inspect and analyze products on production lines. Unlike manual inspections, it operates 24/7 with speed and precision.

Key applications of Machine Vision include:

- Automated quality inspection: Detects defects such as scratches, deformation, color mismatches, or incorrect dimensions.

- Precision measurement & positioning: Accuracy down to microns supports robotic assembly and machining.

- Barcode & QR code reading: Ensures traceability and efficient logistics management.

- Robot guidance: Provides accurate image-based positioning, enabling faster and more stable robotic operations.

For industries like electronics, automotive, or pharmaceuticals, Machine Vision significantly reduces defective rates, ensures consistent quality, and cuts down manual inspection costs.

IoT – The “Lungs” of Industrial Automation

If Machine Vision acts as the “eyes” of production, IoT serves as the “lungs” that supply vital data to keep systems alive and running.

In industrial automation, IoT enables:

- Real-time data collection: Sensors capture temperature, humidity, pressure, vibration, and more from equipment and the production environment.

- Equipment health monitoring: Continuous analytics detect abnormalities, minimizing unplanned downtime.

- Predictive maintenance: Anticipates failures, optimizes maintenance schedules, and extends equipment lifespan.

- System-wide connectivity: Links data across ERP, MES, and WMS systems to provide a holistic factory overview.

Thanks to IoT, businesses achieve centralized management, cost savings, and agility to respond to production changes.

The Power of Combining Machine Vision and IoT

The true strength lies not only in each technology but in their integration:

- Comprehensive monitoring: Vision detects product defects while IoT tracks machine and environmental conditions.

- Greater accuracy: Image data fused with sensor data delivers multidimensional insights.

- Reduced downtime: Vision flags defects instantly, IoT alerts on equipment issues, enabling faster responses.

- Production optimization: Automated systems can self-adjust, notify engineers, or halt processes when required.

- Continuous improvement: Integrated datasets provide long-term analytics for process optimization.

Real-World Applications Across Industries

- Automotive: Vision inspects welding, painting, and components; IoT monitors robotics and assembly lines.

- Electronics: Vision ensures precise placement of micro-components; IoT safeguards cleanroom conditions.

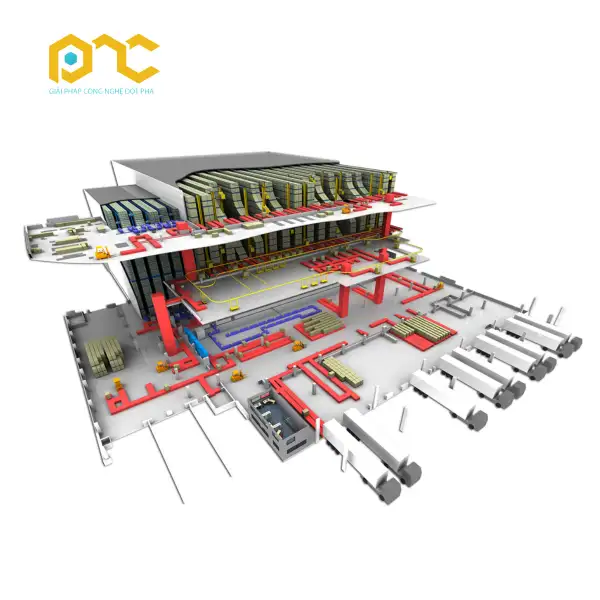

- Smart warehouses & logistics: Vision scans barcodes and inspects packages; IoT monitors temperature, humidity, and warehouse equipment.

This synergy creates not just quality assurance but a sustainable automation ecosystem, helping manufacturers achieve resilience and growth.

PNC TECH – Your Trusted Partner in Smart Automation

In Vietnam, PNC TECH is more than a provider of AGV/AMR systems—the company also integrates Machine Vision and IoT solutions for leading manufacturers.

PNC TECH helps businesses:

- Optimize product quality with Machine Vision.

- Reduce downtime and manage data efficiently with IoT.

- Transition toward Smart Factories with measurable impact.

With PNC TECH as a partner, enterprises boost productivity, ensure quality, lower costs, and strengthen global competitiveness.

Learn more about our services:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn