The automation trend in battery production

In the era of electric vehicles and renewable energy, the demand for high-quality, durable, and safe batteries is soaring. Traditional manual welding methods – prone to errors, labor-intensive, and inconsistent in quality can no longer meet these strict requirements.

PNC TECH introduces housing and busbar welding robots, purpose-built for battery manufacturing. With advanced welding technologies, these robotic systems not only enhance productivity but also optimize costs and guarantee compliance with rigorous technical standards.

Housing welding robots: Strong and leak-proof

The battery housing, which encloses and protects cells against impact, harsh environments, and assists in thermal management, is a critical component in battery manufacturing.

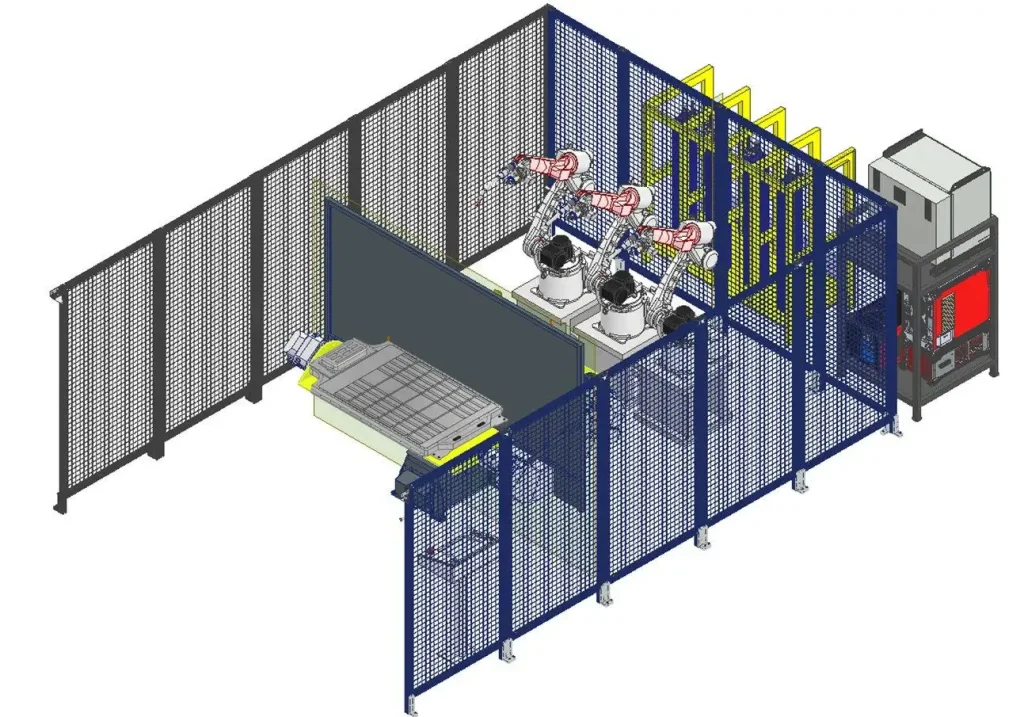

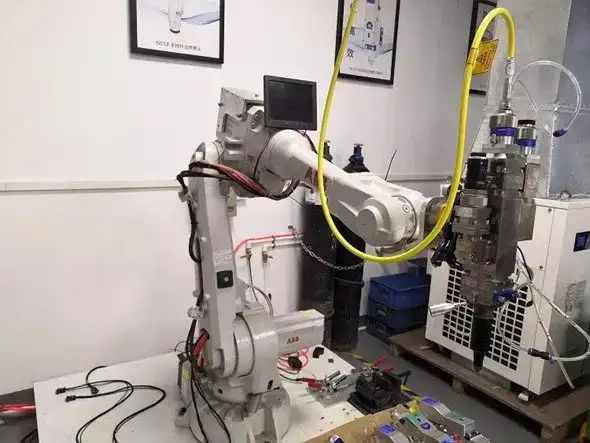

PNC TECH’s housing welding robots employ high-precision laser or automated MIG welding to create durable, airtight joints while minimizing material deformation. The system typically integrates 3-6 axis robots, welding power sources, cooled welding heads, precision fixtures, and safety sensors.

This solution is especially well-suited for electric vehicle batteries and energy storage systems, where welds must be both structurally strong and perfectly sealed to prevent leakage.

Busbar welding robots: Optimizing energy transfer

Busbars serve as conductive connectors between battery cells, requiring welds with high mechanical strength and extremely low resistance to ensure efficient and safe energy transfer.

PNC TECH’s busbar welding robots leverage laser or spot welding, equipped with agile 6-axis robots capable of precise operations in complex, small-scale weld positions. The system also integrates a Vision System that inspects weld quality in real time, ensuring consistency and minimizing defects.

As a result, finished batteries achieve not only excellent energy transfer efficiency but also improved durability over extended use.

Advanced welding technologies and real-world case studies

A standout advantage of PNC TECH’s solutions is the application of non-contact laser welding, which delivers smooth, uniform welds with reduced thermal distortion. Precision fixturing and positioning systems further enable robots to handle housings and busbars of varying shapes and dimensions.

In one real-world project, PNC TECH implemented a 6-axis housing welding robot system combined with automated welding power sources, active cooling, and protective safety enclosures. The outcome: an EV battery manufacturer doubled its productivity, significantly reduced welding defects, and consistently met international quality standards.

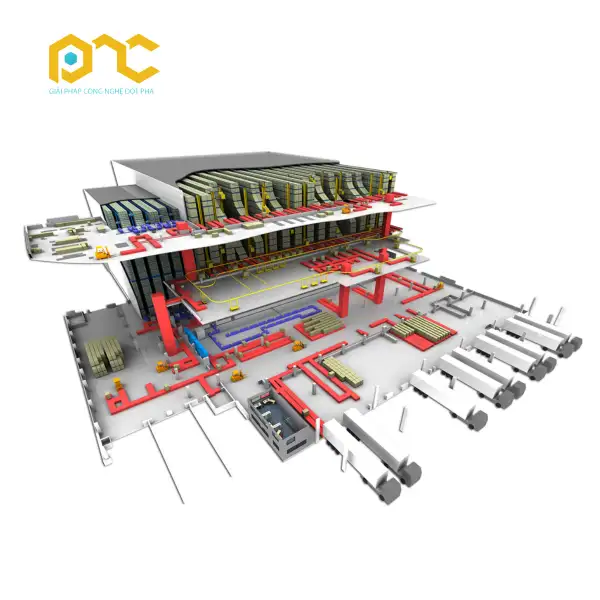

Such case studies highlight how housing and busbar welding robots not only streamline production but also help manufacturers move closer to the Smart Factory model.

PNC TECH – A pioneering partner in battery and EV automation

PNC TECH goes beyond providing equipment – it partners with businesses throughout the entire process: from solution consulting, system design, and installation to operator training and long-term maintenance. Backed by an experienced engineering team and cutting-edge technology, PNC TECH ensures each robotic welding system delivers reliable performance, cost optimization, and sustainable value.

Amid the rapid growth of the battery and electric vehicle industries, PNC TECH’s housing and busbar welding robots stand as a key enabler for manufacturers seeking to strengthen competitiveness, reduce reliance on manual labor, and achieve global quality benchmarks.

Tìm hiểu thêm về dịch vụ của chúng tôi:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn