Strategic Investment in Jig Welding – A Key to Production Efficiency

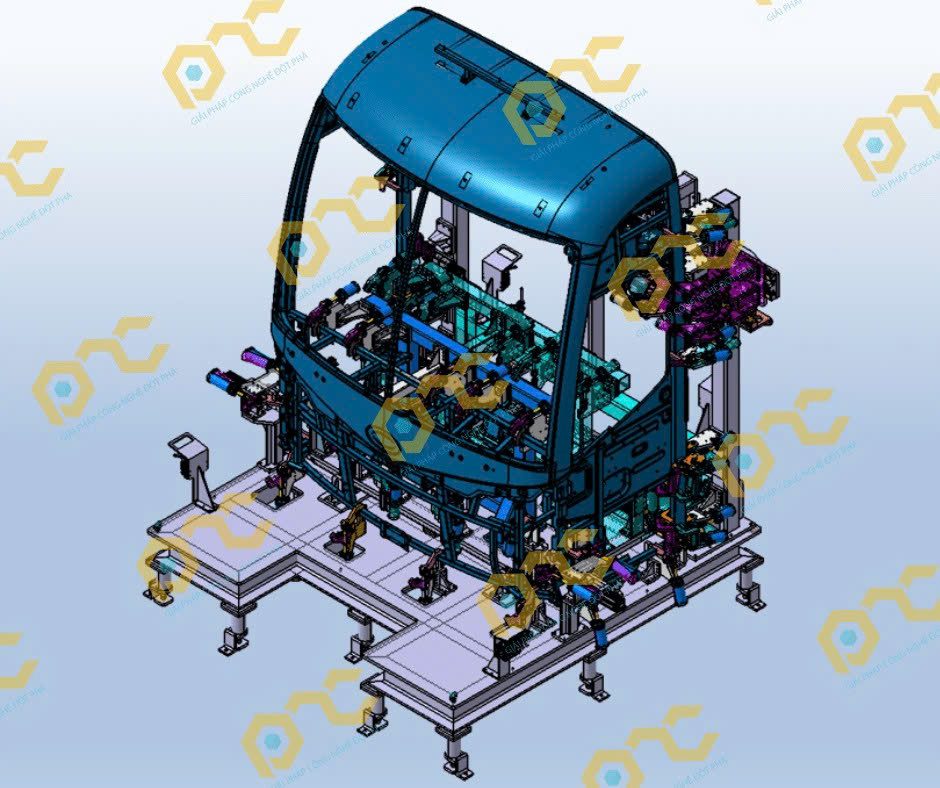

At PNC TECH, we deliver complete jig welding solutions, not just standalone products. Each system is custom-designed to address production bottlenecks and enhance operational capabilities.

Investing in our jig welding systems means achieving:

- Higher accuracy: Precise positioning for consistent, defect-free welds, even in complex assemblies like automotive frames and suspension systems.

- Faster production cycles: Automated or semi-automated processes reduce setup time and manual adjustments.

- Optimized production flow: Integrated layout design ensures seamless material movement and reduces process delays.

- Lower long-term costs: Durable jigs minimize rework, labor costs, and material waste.

- Quality compliance: Meet stringent international quality standards for welding and export certification.

With a dedicated engineering team and a closed-loop production process, PNC TECH supports businesses from concept to implementation—building modern, scalable, and future-ready manufacturing systems.

International Project Experience – Meeting Strict Standards

PNC TECH’s reputation extends far beyond the domestic market. The company has successfully implemented numerous jig welding projects for partners across Europe and Asia, including major brands such as Nissan, Opel, and several OEM factories in Malaysia, Thailand, and Indonesia.

These projects required strict compliance with international standards for quality, safety, and operational durability—standards that very few local companies can meet.

In every project, PNC TECH not only delivered technical excellence but also optimized costs and implementation timelines by maintaining full control over the entire process—from design to manufacturing and installation.

When Vietnamese businesses need optimal and self-sufficient manufacturing solutions, choosing a reliable jig welding partner is essential. PNC TECH is a pioneer in Vietnam, mastering the entire jig welding solution process—from consulting and design to delivering modern, turnkey systems.

We do not rely on mass-imported equipment; instead, we use cutting-edge technology from leading global brands, apply advanced simulation software, and execute projects with a highly experienced engineering team.

If you want to boost production efficiency and automate your factory, PNC TECH is the partner you can trust. Contact PNC TECH today for 1-on-1 expert support and a tailored, optimal solution for your production line.

Learn more about our services:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn