Overview of Goods Sorting Robots

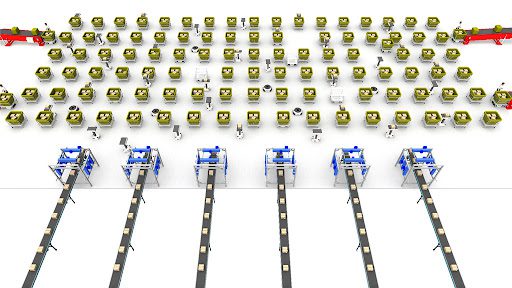

Goods sorting robots are automated devices designed to perform sorting and organizing tasks in warehouses and manufacturing facilities. They utilize advanced technologies such as Artificial Intelligence (AI) and Machine Learning to identify, classify, and transport goods according to specific criteria, such as size, weight, barcodes, or QR codes.

These robots can operate independently or integrate with Warehouse Management Systems (WMS), optimizing workflow, minimizing errors, and improving overall operational efficiency.

Loading Guidelines for Goods on Robots

The way items are loaded onto sorting robots depends on factors such as size, weight, and shape. Proper loading maximizes storage space on the robot and ensures safe transportation. Typical procedures include:

- Stacking by height: To optimize space, goods can be stacked vertically.

- Stacking by weight: Heavy items should be placed at the bottom to ensure stability during movement.

- Grouping by size: Items of similar dimensions can be grouped together for easier management and transport.

(Explore other solutions offered by PNC)

Advantages & Limitations of Goods Sorting Robots

Advantages

- Flexibility: Robots can quickly adapt to changing production requirements or customer demands, increasing system responsiveness.

- Energy efficiency: Robots operate continuously and efficiently without the need for breaks, saving energy compared to human labor.

- Customizable and scalable layouts: Robots can be easily reprogrammed or adjusted to fit new processes or warehouse layouts, providing system flexibility.

Limitations

- Technical expertise required: Effective operation requires skilled technicians and engineers familiar with smart traffic models like PNC Tech, who understand robot operations and can design solutions tailored to each customer’s specific needs.

- High initial investment: The cost of purchasing and maintaining sorting robot systems can be significant, so companies must weigh upfront expenses against long-term benefits.

We hope this article helps you better understand goods sorting robots—their operation, benefits, and limitations—before making an investment decision. For more information or detailed consultation, contact PNC TECH. We are committed to providing advice tailored to each client’s current situation and goals and will propose solutions that best meet your operational requirements.