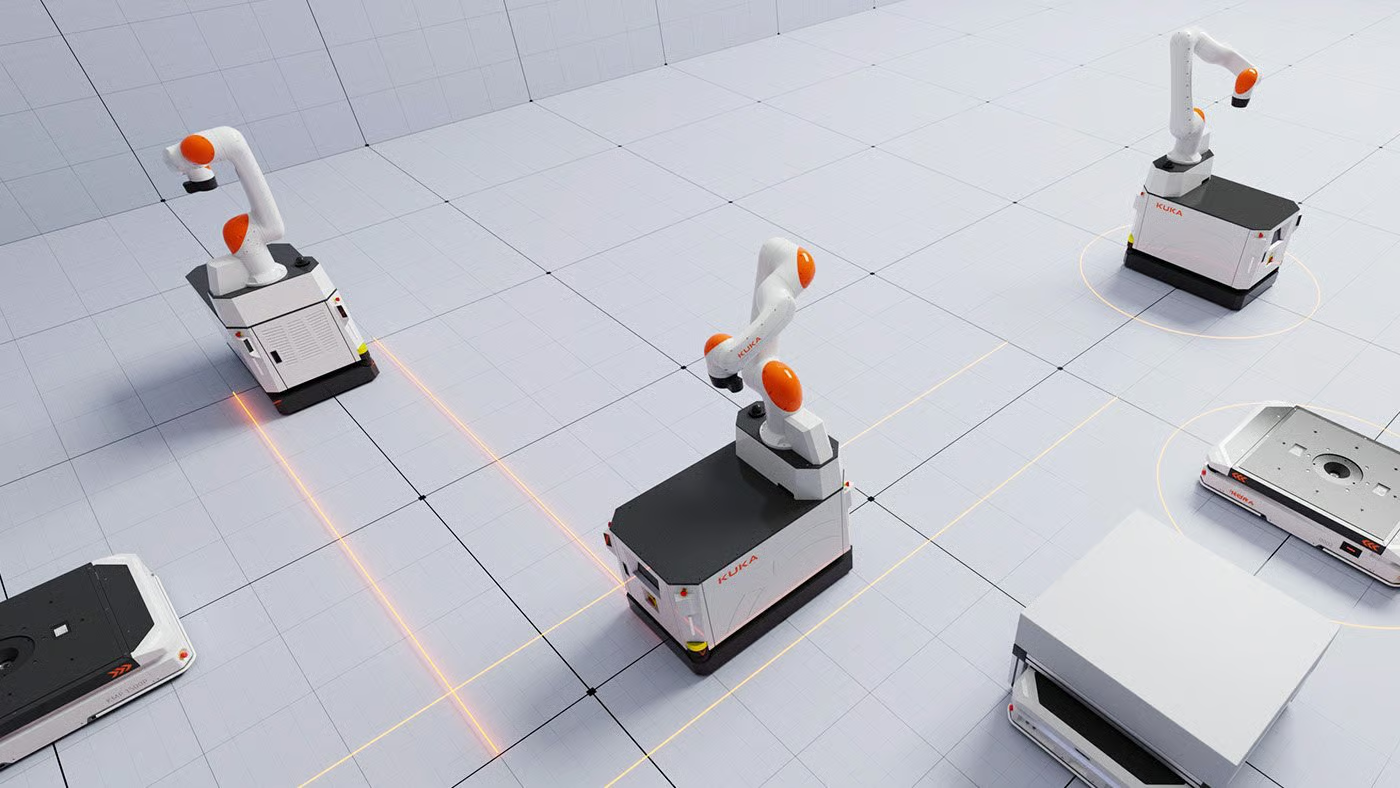

The solution of using AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots) is a pivotal technological advancement, helping to optimize in-plant transportation processes, improve operational efficiency, and minimize production risks.

Benefits of AGV/AMR in Renewable Energy Manufacturing

Once deployed, AGVs/AMRs deliver practical benefits, creating major differences in production and logistics management:

- Increased productivity and transport efficiency: Robots operate continuously, automatically transporting solar modules, turbine blades, or heavy components, reducing dependence on manual labor.

- Enhanced safety: Thanks to sensors and collision-avoidance technologies, AGVs/AMRs operate safely even in environments with many machines and workers.

- Reduced operating costs: Accurate and stable transport reduces component damage and limits risks in storage and assembly.

- Adaptability to complex environments: AMRs can flexibly navigate plants with complex layouts, changing or expanding production lines.

Accurate data management: Integrated with Warehouse Management Systems (WMS) and Manufacturing Execution Systems (MES), AGVs/AMRs enable data collection, maintenance optimization, and improved overall management capacity.

AGVs/AMRs in Action

Applications in battery and renewable energy plants:

- AGV: Best suited for fixed routes, operating reliably according to pre-programmed scenarios. Commonly used for transporting solar modules or raw material pallets along predefined paths inside the factory.

- AMR: More flexible, using autonomous mapping and localization (SLAM) technology to navigate effectively in dynamic environments with people and machines. Suitable for areas like wind turbine blade assembly or constantly changing production lines.

The combination of AGVs and AMRs allows factories to maintain stability while ensuring flexibility, meeting the growing demands of renewable energy production.

Specific Requirements of the Renewable Energy Industry

Battery and renewable energy manufacturing requires automated transport systems to meet strict demands:

- Heavy loads: Wind blades, solar modules, and energy storage components are large and heavy, requiring robots with stable lifting capacity and minimal vibration.

- High precision: Accurate positioning and assembly ensure safety and product quality.

Challenging environments: Plants have numerous obstacles and constantly changing workspaces, requiring robots with collision avoidance and optimized path planning.

Technological Solutions for AGV/AMR

To meet these requirements, AGVs/AMRs in the renewable energy sector integrate advanced technologies:

- SLAM (Simultaneous Localization and Mapping): Enables robots to autonomously create maps, locate precisely, and plan optimized routes.

- LIDAR sensors: Functioning as the “eyes” of the robots, scanning 2D/3D spaces to detect obstacles and adjust paths.

- Artificial Intelligence (AI): Analyzes sensor data, optimizes routes based on traffic density, and predicts maintenance needs to minimize downtime.

- IoT and system integration: Connecting robots with WMS and MES for real-time coordination and operational monitoring.

Through this combination, AGVs/AMRs achieve robust, precise, and flexible operations in the demanding environments of renewable energy manufacturing.

The adoption of AGVs and AMRs in battery and renewable energy plants is an inevitable trend, contributing to higher production efficiency, improved safety, and reduced operational costs. With advanced technologies such as SLAM, LIDAR, AI, and IoT, autonomous robotic systems not only replace manual labor but also foster sustainable growth aligned with the future requirements of the green energy industry.

Learn more about our services:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn