Traditional Warehousing in the Age of E-commerce

As Vietnamese businesses accelerate digital transformation and modernize their supply chains, choosing the right warehouse model plays a vital role in optimizing efficiency, reducing costs, and strengthening competitiveness.

Today, two popular options are traditional warehouses and ASRS (Automated Storage and Retrieval Systems). So which solution is the right fit for your business?

As a pioneer in warehouse automation, PNC TECH has successfully implemented numerous ASRS projects for manufacturers and logistics companies. Through this article, we will help you clearly understand the differences between the two models and provide guidance on selecting the one that best suits your business goals and scale.

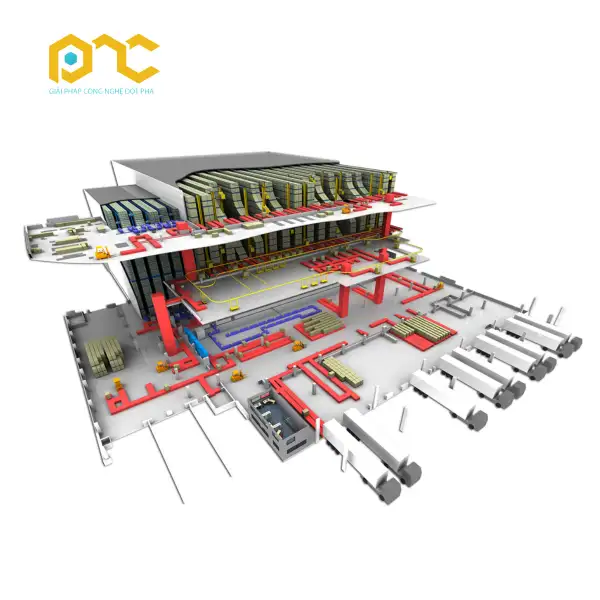

What is ASRS?

ASRS (Automated Storage and Retrieval System) is a fully automated solution for storing and retrieving goods, using electromechanical devices such as stacker cranes, shuttle robots, conveyors, vertical lift modules (VLMs), and multi-tier racking systems — all synchronized and controlled through warehouse management software (WMS).

In Vietnam, PNC TECH is among the few companies capable of designing and integrating both ASRS hardware and software, customized to specific industries and business scales.

Detailed Comparison: Traditional Warehouse vs. ASRS

| Criteria | Traditional Warehouse | ASRS |

|---|---|---|

| Space utilization | Limited by warehouse height, requires multiple aisles | Maximizes vertical height (up to 40m), 2–3x higher storage capacity |

| Labor | Relies heavily on manual work | Highly automated, reduces workforce and errors |

| Processing speed | Slow, requires frequent movement, hard to optimize | Fast picking/put-away, from seconds to minutes |

| Inventory accuracy | Manual updates, prone to errors | Real-time management with high accuracy |

| Scalability | Requires larger land area | Modular design, expandable without extra land |

| Long-term cost | Low upfront cost but high operating expenses | High initial cost, long-term operational savings |

| Workplace safety | High risks from manual handling | Minimizes accidents, cleaner work environment |

| Technology integration | Limited | Easily integrates with ERP, WMS, AI, IoT |

What Do Businesses Gain from Investing in ASRS?

Investing in ASRS is not just about upgrading warehouses — it is the foundation for businesses to accelerate operational efficiency and management capabilities. Here are five core values companies will achieve:

- Maximized storage space: 2–3 times higher capacity compared to traditional warehouses, thanks to smart racking and vertical utilization.

- Faster order processing: Automated, accurate operations shorten order fulfillment and delivery times.

- Reduced labor and operating costs: Fewer staff required, lower energy consumption, and optimized operations overall.

- Real-time, accurate inventory control: PNC TECH’s integrated WMS tracks, analyzes, and alerts inventory instantly.

- Scalable and technology-ready: Seamlessly connects with ERP, MES, AI, and IoT to build a fully smart factory ecosystem.

When Should You Choose a Traditional Warehouse?

Despite its advantages, ASRS may not always be the right choice. Traditional warehouses remain suitable if:

- The business is small with low inventory volume

- Inbound and outbound frequency is not high

- Initial investment budget is limited

However, if your business plans to expand or join modern supply chains, PNC TECH recommends developing a roadmap toward automated warehousing to be ready for the future.

Key Considerations Before Investing in ASRS

(Explore more PNC Tech’s solutions)

Smart Warehouses Implemented by PNC

Implementing ASRS requires careful evaluation of financial capacity, industry specifics, and long-term objectives. Important considerations include:

- High initial investment: However, operational efficiency ensures payback within 3–5 years and long-term savings.

- Technical requirements: PNC TECH offers full-package services — consulting, design, training, and maintenance — ensuring effective system operation from day one.

- Not ideal for low-turnover inventory: PNC supports ROI assessment and designs solutions aligned with actual operating rhythms.

- Customization required: With extensive experience implementing ASRS nationwide, PNC TECH tailors designs and control software to meet the unique needs of each industry.

ASRS does not only help businesses handle goods faster, more accurately, and at lower costs — it also serves as a core enabler of digital transformation and smart supply chains.

With a proven track record of successful ASRS projects across Vietnam, PNC TECH is ready to accompany businesses in upgrading warehousing operations — from consulting to full-scale integration — helping optimize costs, improve efficiency, and stay ahead of the Industry 4.0 curve.

Discover more about our services:

📞 Hotline: (+84) 919 247 843

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn