The automation trend in glue dispensing

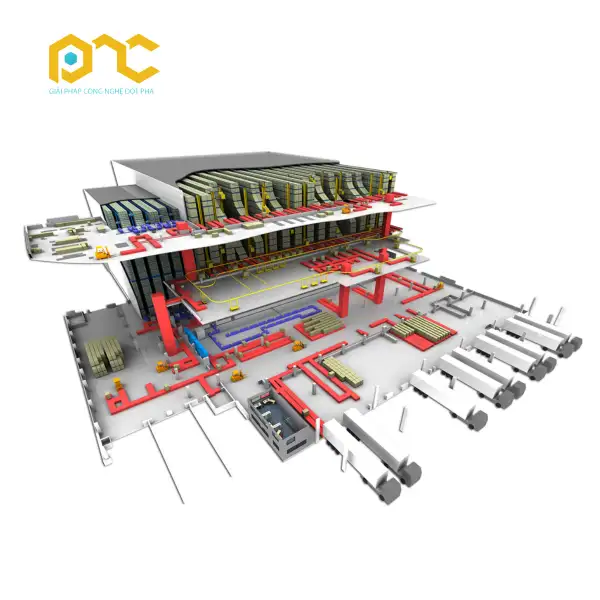

In the era of Industry 4.0, optimizing production processes is a vital factor for every manufacturer. Manual glue dispensing is often time-consuming, prone to errors, and leads to material waste. To address this, PNC TECH introduces its automatic glue dispensing robot – a solution widely applied in electronics, automotive, packaging, and household appliances. This technology not only boosts productivity but also ensures accuracy, consistency, and material savings, paving the way toward the modern Smart Factory model.

What is an automatic glue dispensing robot?

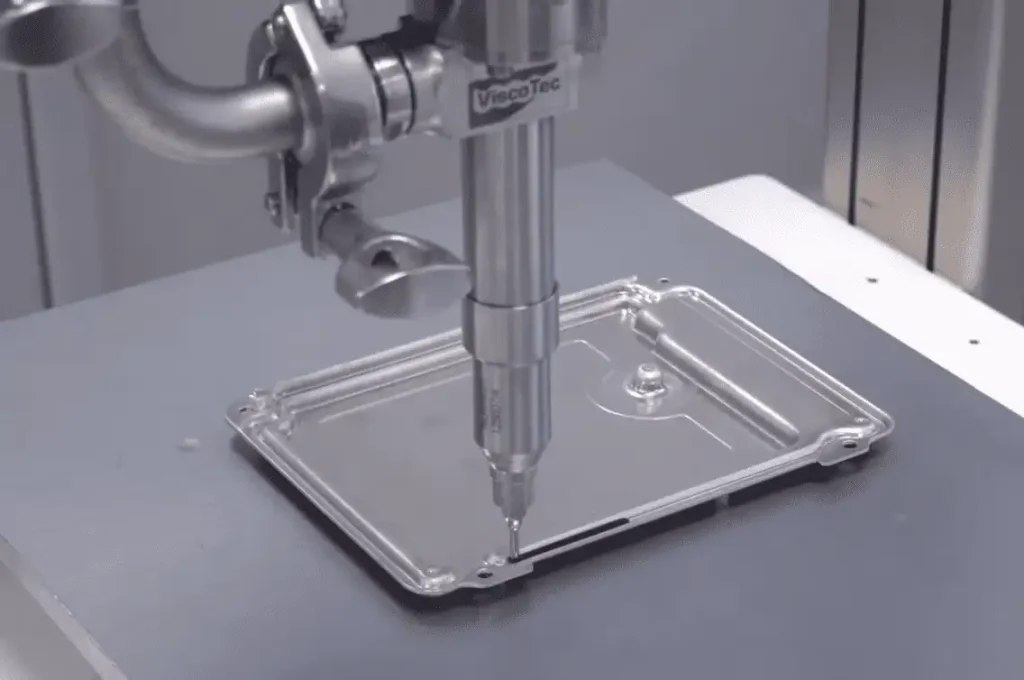

An automatic glue dispensing robot is a robotic arm system programmed to apply or spray adhesive on product surfaces with high speed and absolute precision. These robots can operate at speeds of up to 5.05 m/s, ensuring continuous and stable performance while fully replacing manual labor in complex gluing tasks.

A standout feature of PNC TECH’s glue dispensing robot is its positional accuracy of just 0.01 mm. This ensures adhesive is applied evenly and correctly every time, minimizing issues such as smearing, overflow, or insufficient glue – common drawbacks of manual methods.

How the robot operates in production lines

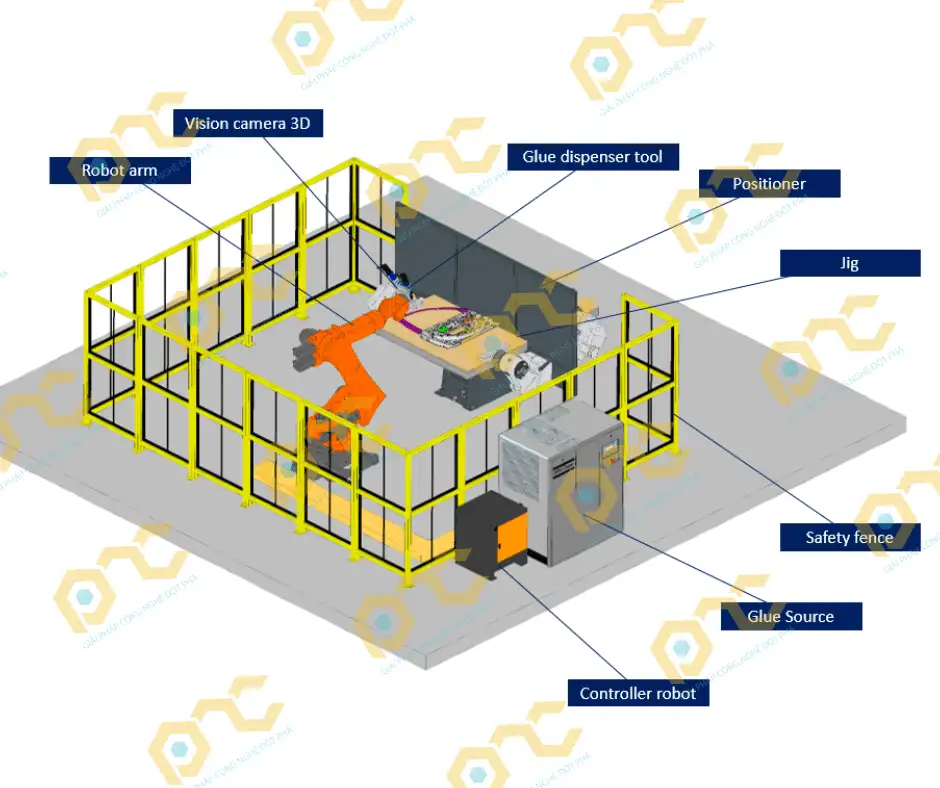

Unlike traditional manual methods that depend on worker skills, glue dispensing robots run based on pre-programmed instructions:

- Precise control: The robot identifies the exact position and applies the required adhesive amount.

- Real-time monitoring: Equipped with sensors and cameras, the robot can adjust pressure and adhesive flow instantly.

- Seamless integration: Easily connects with other systems such as pick-and-place robots or assembly robots, forming a complete automated production line.

This coordination allows manufacturing to run faster, more synchronized, and with stable product quality.

Multi-industry applications of glue dispensing robots

With high flexibility, PNC TECH’s glue dispensing robots can be applied across various industries:

- Electronics: Applying glue to circuit boards, components, casings of phones, and other electronic devices requiring precision.

- Automotive: Sealing glass, door gaskets, and assembly parts that require durability and airtightness.

- Packaging & composites: Applying adhesives in film lamination, packaging processes, or composite production.

- Household appliances & consumer goods: Ensuring durability, aesthetics, and consistency of finished products.

Thanks to flexible programming, the robots can handle diverse product shapes and sizes without requiring major system adjustments.

Key benefits of using PNC TECH glue dispensing robots

Implementing automatic glue dispensing solutions delivers outstanding advantages for manufacturers:

- Increased productivity: Robots operate continuously, boosting product output and reducing production time.

- High precision & consistency: Every product is glued uniformly and accurately, meeting international standards.

- Material savings: Optimized adhesive usage minimizes waste and lowers production costs.

- Improved workplace safety: Robots replace humans in handling adhesives, reducing risks of exposure and occupational hazards.

- Easy integration: PNC TECH solutions support seamless connection with monitoring and production management systems for real-time quality control.

(Explore more solutions of PNC Tech)

PNC TECH – A trusted automation partner

Beyond providing glue dispensing robots, PNC TECH accompanies businesses throughout the entire journey: consultation, solution design, installation, operator training, and maintenance. With a team of skilled engineers and advanced technology, PNC TECH is committed to delivering optimal, durable, and customized automation solutions for each factory.

Learn more about our services:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn