In the era of Industry 4.0, intralogistics has become the “lifeline” of smart factories and warehouses. AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot)—autonomous robots integrated with SLAM, LIDAR, and AI—do more than optimize internal transportation; they enhance productivity, reduce costs, and ensure safety.

PNC TECH is at the forefront of bringing AGV/AMR solutions to Vietnam’s automotive, electronics, energy, and logistics industries, accompanying enterprises on their journey to build modern, intelligent production systems.

The Inevitable Step in Intralogistics 4.0

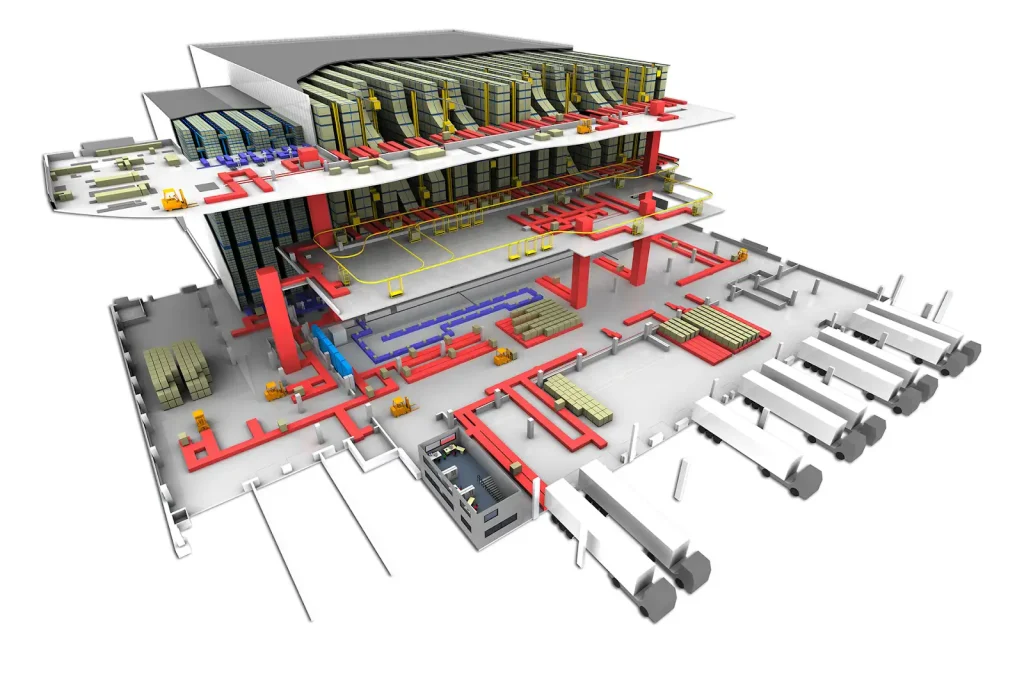

Amid fierce global industrial competition, internal transportation automation (intralogistics) has become a key pillar of smart factories and warehouses. Two standout technologies are AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot)—autonomous robots that optimize the flow of materials, from car frames, battery modules, and electronic components to palletized goods.

In Vietnam, PNC TECH pioneers AGV/AMR implementation in automotive, electronics, and energy projects, delivering modern, safe, and cost-efficient transportation solutions.

AGV vs. AMR: Definitions and Differences

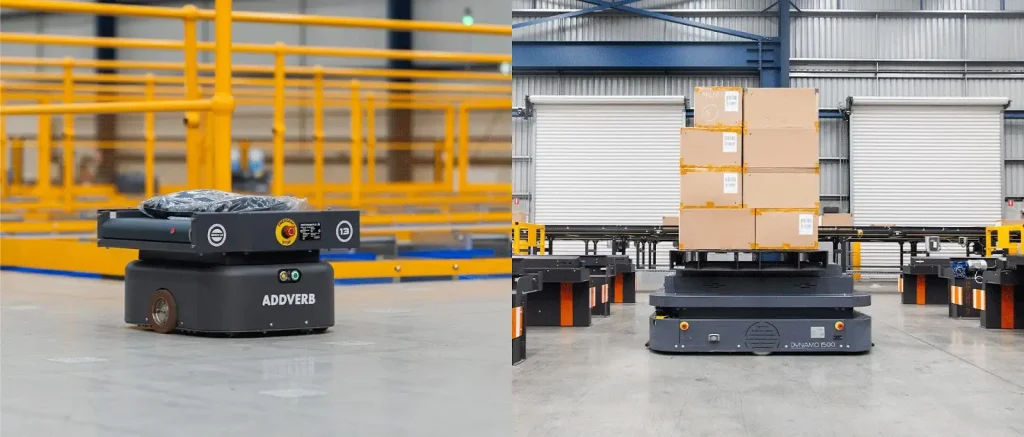

- AGV: Operates along fixed paths (magnetic tape, sensors, QR codes), suitable for stable production environments.

- AMR: Navigates autonomously using SLAM, LIDAR, and AI, capable of 3D mapping and optimal path planning, offering greater flexibility in dynamic environments.

By combining AGV and AMR, businesses achieve both operational stability and production flexibility.

Core Technologies: SLAM, LIDAR, and AI

Modern robots integrate multiple intelligent technologies:

- SLAM (Simultaneous Localization and Mapping): Enables robots to move while mapping their surroundings, adapting to complex environments without fixed pathways.

- LIDAR: Uses laser scanning to detect obstacles and create accurate 3D maps.

- AI: Analyzes sensor data, optimizes routes, coordinates multiple robots, and learns to adapt to operational changes.

Thanks to these technologies, AGV/AMR can navigate safely and efficiently across multi-level, multi-zone manufacturing and warehouse environments.

Key Advantages of AGV/AMR in Intralogistics

- Space Optimization: Maneuvering through narrow aisles and blind spots, maximizing factory floor usage.

- Labor Savings: Handling heavy components, battery modules, and palletized goods to replace manual labor.

- Productivity Boost: Operating 24/7 with minimal errors and reduced downtime.

- High Safety Standards: Sensors and AI prevent collisions, ensuring worker and equipment safety.

- Scalability: Easy integration with WMS (Warehouse Management System), MES, or ERP systems for future upgrades.

Real-World Applications Across Industries

- Automotive Industry

AGV/AMR transports car frames, battery modules, and engines between assembly stages, synchronized with Smart Factory models—reducing waiting times and improving production line efficiency. - Electronics Industry

Autonomous robots move circuit boards and delicate electronic modules across SMT lines, assembly areas, and inspection stations—minimizing manual handling and component damage. - Renewable Energy Industry

AGV/AMR handles solar panels, wind turbine blades, and energy storage modules, ensuring safe transport during installation and maintenance.

PNC TECH – AGV/AMR Implementation Partner in Vietnam

With over 10 years of automation experience in South Korea, Japan, and Vietnam, PNC TECH delivers end-to-end services:

- Consulting solutions tailored to specific production needs.

- Designing and integrating AGV/AMR with existing management systems.

- Training for operation, maintenance, and future system scaling.

PNC TECH is not just a technology supplier but a trusted partner—helping businesses accelerate their journey toward Smart Factory 4.0.

AGV and AMR are reshaping intralogistics—from automotive plants to smart warehouses. The synergy of SLAM, LIDAR, and AI enables precise, safe, and efficient operations. With PNC TECH as your partner, Vietnamese enterprises can confidently adopt autonomous robotics to optimize costs, boost productivity, and strengthen competitiveness in the Industry 4.0 era.

Tìm hiểu thêm về dịch vụ của chúng tôi:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn