In the era of Industry 4.0, optimizing manufacturing and logistics processes has become a key factor in determining a company’s competitiveness. One of the most breakthrough solutions today is the ASRS (Automated Storage and Retrieval System). This is not just a technology, but a powerful transformation in the way factories and logistics centers operate—from storage and inventory management to space optimization. In this article, PNC Tech will dive into the definition, components, and outstanding benefits of ASRS, helping businesses gain a comprehensive perspective.

What is ASRS? The Concept of a Smart Warehouse System

ASRS stands for Automated Storage and Retrieval System, a comprehensive automation solution for warehouses. It uses robotic equipment and computer software to perform storage, retrieval, and handling of goods fully automatically and with high accuracy.

With ASRS, the entire process—from placing goods on racks, organizing, managing locations, to retrieving items—is computer-controlled, eliminating the need for human intervention. This not only removes errors but also increases processing speed many times compared to traditional methods. PNC Tech positions itself as a pioneer in integrating technology and developing automation applications, delivering professional and optimized ASRS solutions to customers.

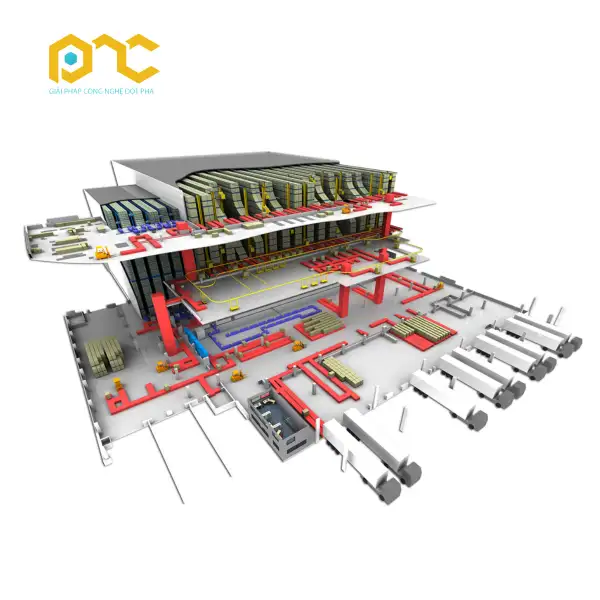

Structure and Operating Principles of ASRS

Depending on demand and scale, the components of an ASRS can be customized for maximum efficiency. The main components include:

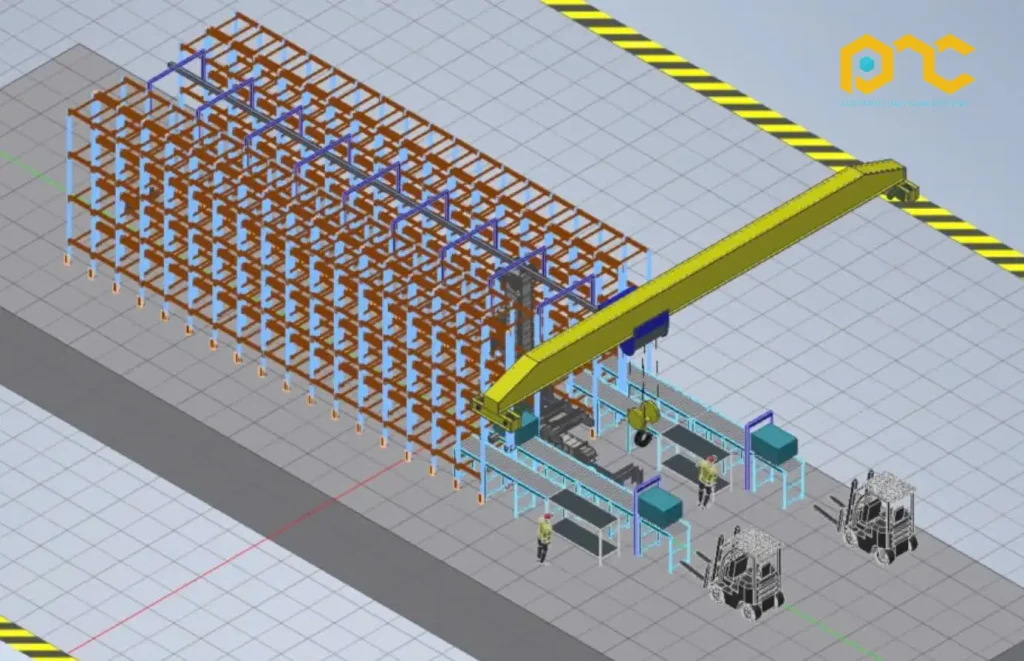

- Racking System: The backbone of the warehouse. ASRS racks are specially designed for high-density storage, maximizing warehouse height usage.

- Automated Robots (Stacker Cranes): These are automated cranes or lifters that move along rails to retrieve and place goods at precise rack positions, or transfer them to packaging areas.

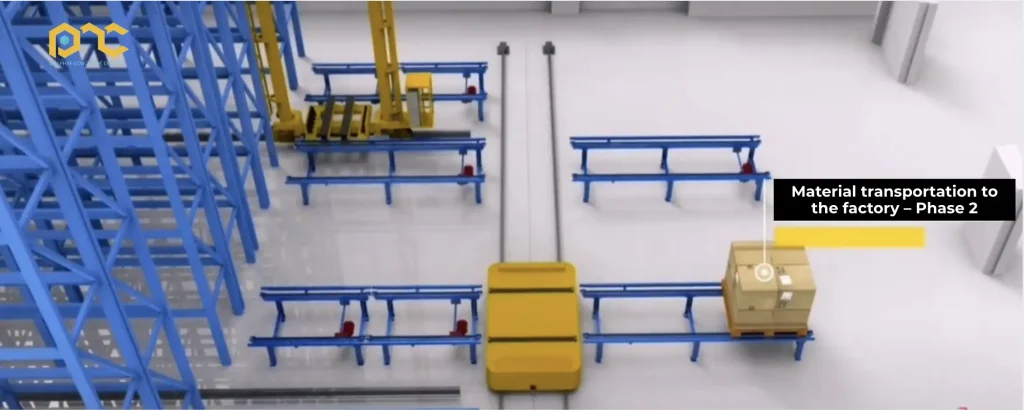

- Conveyor System: Includes conveyors and autonomous vehicles (AGVs/AMRs) that transport goods between the receiving area and the stacker cranes.

- Warehouse Management/Control Software (WMS/WCS): The central control system. WMS manages inventory, tracks item locations, and sends commands for automated equipment to operate according to workflow.

Operating principle:

When goods enter the warehouse, the WMS receives the information, then instructs the stacker crane to move to an available slot and store the goods. Conversely, when goods are requested, the WMS locates them, commands the crane to retrieve them, and delivers them to the outbound area. This process is fully automated, ensuring near-perfect speed and accuracy.

Key Advantages of ASRS in Manufacturing & Logistics

ASRS solutions deliver significant benefits, helping businesses enhance competitiveness and optimize resources:

- Space Optimization: ASRS maximizes warehouse height, increasing storage capacity by up to 85% compared to traditional warehouses.

- Speed & Efficiency: Automated systems can run 24/7 with retrieval speeds many times faster than humans, boosting throughput.

- High Accuracy: With computer and robotic control, ASRS achieves up to 99.99% accuracy, minimizing inventory management errors.

- Labor Cost Savings: Automation reduces reliance on manual labor, cuts operating costs, and improves workplace safety.

- Effective Management: Integrated WMS provides real-time inventory data, enabling businesses to easily monitor and make timely decisions.

Why Choose PNC Tech’s ASRS Solutions?

PNC Tech is a trusted technology partner with the motto “Professional and Creative.” We deliver customized ASRS systems tailored to each business, exemplified by our automated warehouse project at VinFast. Our team of engineers, with experience in Germany and Japan, fully manage the process from design to deployment.

Additionally, we provide comprehensive after-sales services: scheduled maintenance, 24/7 support, and operator training—ensuring long-term stability and reliability.

Learn more about our services:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn