In modern industrial production, robots only reach their full potential when paired with precise jigs (fixtures) – the key element that determines stability, productivity, and product quality. With over 10 years of experience in South Korea, Japan, and Vietnam, PNC TECH is a pioneer in jig design and manufacturing, offering optimized solutions for automotive and mechanical production lines.

1. Why Accurate Jigs Are Critical for Robot Efficiency

An advanced robotic line cannot operate effectively without reliable jigs. Robots execute tasks based on pre-fixed positions of components, meaning any inaccuracy in the jig compromises the entire system’s precision and stability. High-quality jigs bring significant benefits:

- Absolute positioning: Ensures robots operate at the correct point and trajectory, minimizing welding errors and machining deviations.

- Workpiece stability: Prevents displacement under force, guaranteeing consistent welds and precise shapes.

- Higher speed & automation: Stable fixtures allow robots to operate continuously at high speed, boosting productivity.

- Cost & waste reduction: Accurate jigs reduce defects, improve efficiency, and ensure long-term safety for both equipment and operators.

2. Key Design Criteria for Effective Jigs

To meet the rigorous demands of modern manufacturing, jig design must be meticulously engineered from material selection to durability and usability. PNC TECH applies international standards to ensure sustainable efficiency for clients:

- Materials: Alloy steel or special-grade aluminum to resist heat, wear, and deformation.

- Structural stability: Rigid construction with multi-point clamping systems to evenly distribute force.

- Ease of installation & adjustment: Quick setup and part replacement reduce downtime during product changeovers.

- Durability & maintenance: Long-lasting performance in harsh environments, with simple designs for easy servicing and cost optimization.

(Explore more of our solutions)

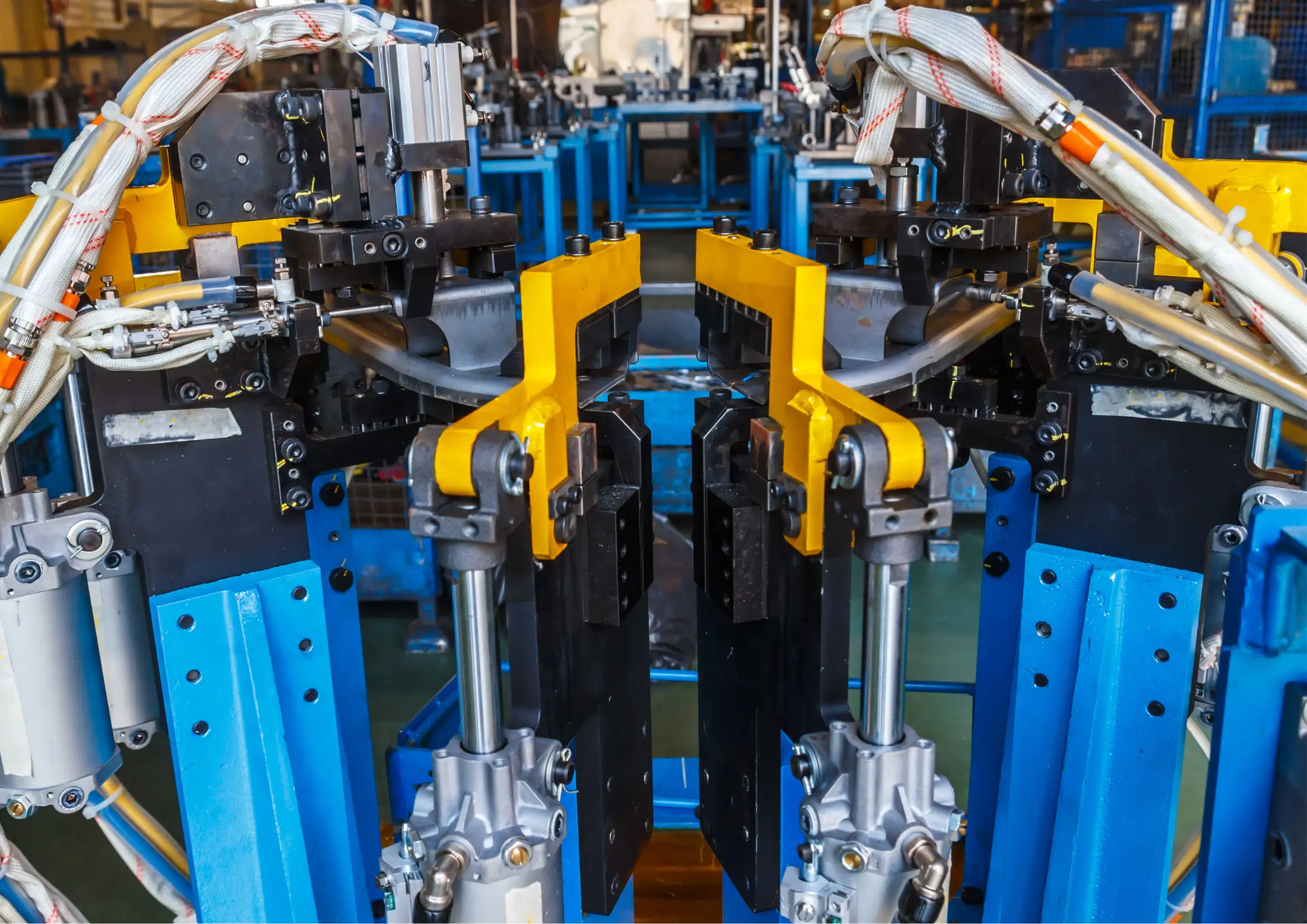

3. Case Study – Welding Jig for Nissan

In automotive manufacturing, precision, durability, and stability are paramount. For Nissan – a globally renowned Japanese automaker known for strict quality standards – the integration of high-precision welding jigs was crucial.

PNC TECH successfully designed and manufactured a specialized welding jig for Nissan, featuring:

- Detailed 3D design: Full process simulation for accurate welding positioning.

- High-grade alloy steel: Heat-resistant, wear-proof, and deformation-free over long-term use.

- CNC precision machining: Eliminating errors, enhancing durability and consistency.

- Strict assembly & inspection: In compliance with JIS and international quality standards.

Results for Nissan:

- Continuous 24/7 production with consistent performance.

- Over 99% of welds meeting quality standards.

- Reduced errors, minimized maintenance, and significant operational cost savings.

This project not only highlights PNC TECH’s jig manufacturing expertise but also demonstrates the capability of a Vietnamese enterprise to deliver high-tech solutions to global corporations.

With a team of engineers boasting over a decade of hands-on experience and successful project delivery in multiple markets, PNC TECH is committed to delivering high-quality jig design and manufacturing solutions that meet international standards and diverse industrial needs.

Learn more about our services:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn