Overview of Grinding & Polishing Robots

In industries requirng high-quality surface finishing such as automotive, aerospace, precision engineering, and medical equipment, metal surface treatment is a critical yet time-consuming and labor-intensive process. Grinding and polishing robots have emerged as intelligent automation solutions, delivering high precision, consistent results, enhanced labor safety, and improved operational efficiency.

In this article, PNC Tech will help you gain a deeper understanding of grinding robots, their structure, workflow, and applications in industrial production.

System Structure and Key Components

A grinding and polishing robot system integrates multiple components working in synchronization:

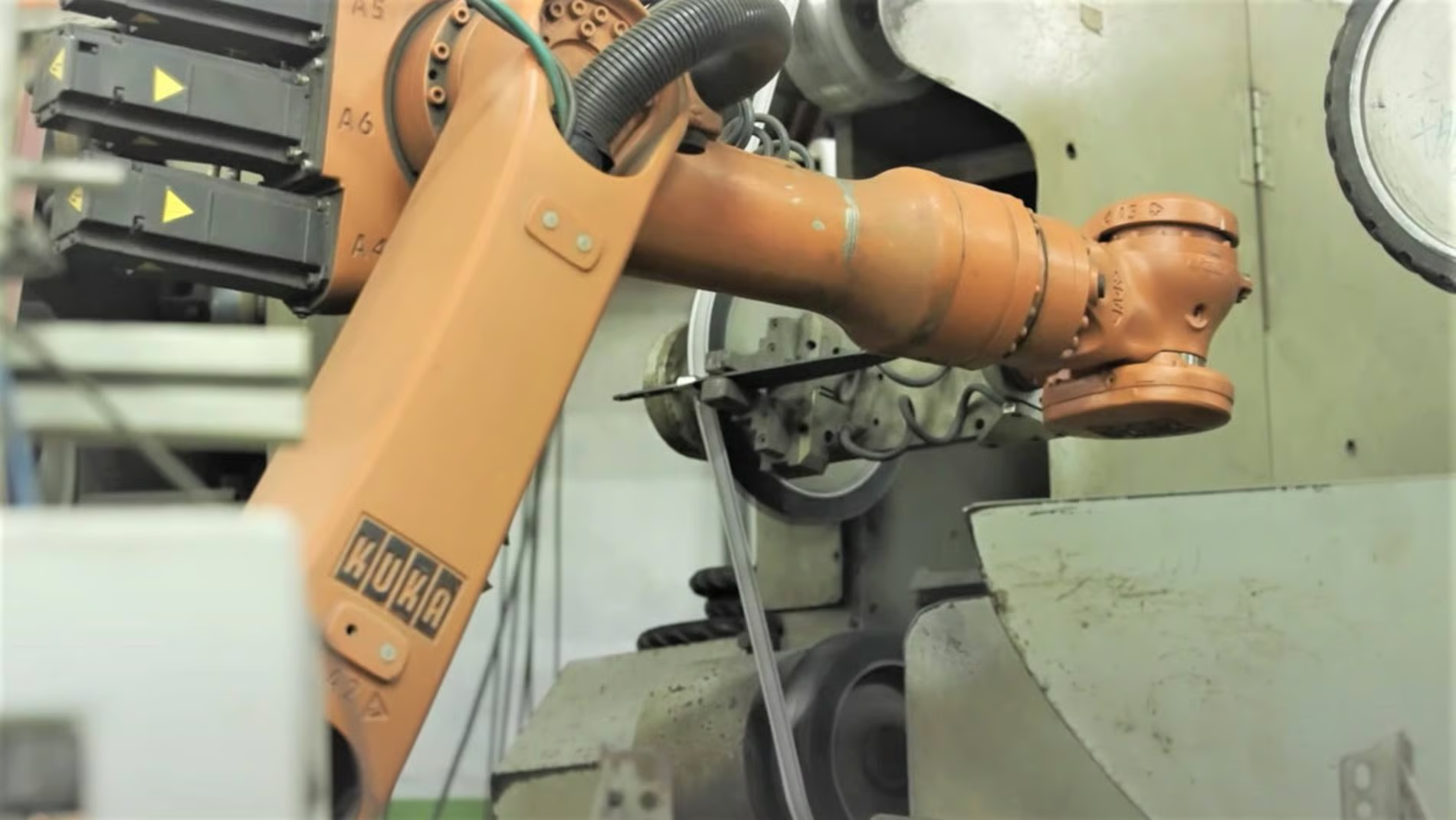

- 6-axis industrial robot arm: Allows flexible movement around objects of various shapes, including sheets, pipes, complex components, or items of different sizes.

- Versatile grinding/polishing heads: Depending on surface and material requirements, the system can use sand belts, buffing wheels, grinding discs, rollers, or felt wheels.

- Force, position, and torque sensors: Ensure the robot adjusts pressure in real time, maintaining stability during operation.

- Computer vision, 3D sensors, and optical systems: Enable precise detection of areas to be processed, automatically aligning for each specific product.

- Flexible control software: Facilitates easy programming, trajectory modification, real-time monitoring and correction, and multitasking integration on the production line.

Automated Operation Workflow

The grinding and polishing system operates sequentially as follows:

- Product preparation:

Items are secured using fixtures or smart rotary tables, allowing the robot to access surfaces accurately. - Detection and alignment:

The robot uses sensors to identify surface features and automatically adjusts pressure to minimize errors and improve uniformity. - Grinding/Polishing execution:

The robot arm follows programmed trajectories to polish the entire surface evenly. When supported by a rotary table, the robot can reach multiple angles, enhancing finishing efficiency. - Inspection & finishing:

Optical sensors and machine vision assess surface quality. If defects are detected, the robot can automatically re-polish. Integrated dust extraction maintains a clean work environment. - Product output:

Finished products are removed from the system for the next stage, such as packaging or assembly.

Advantages & Limitations of Grinding & Polishing Robots

– Advantages:

- High precision and uniform quality: Sensors and machine vision ensure consistent force control, producing smooth, glossy surfaces with minimal variation.

- Increased productivity – reduced labor: Robots operate 24/7, reducing processing time and manual labor while increasing the proportion of standard-quality products.

- Enhanced worker safety: Reduces exposure to dust, noise, and hazardous manual operations such as hand grinding or chemical handling.

- Programming flexibility and product adaptability: Easily reprogrammable for different materials, shapes, and sizes, suitable for diverse production lines.

– Limitations:

- High initial investment: Implementation requires significant budgets for robots, sensors, and control software, better suited for long-term investments.

- Technical expertise required: Operation, programming, and maintenance demand personnel skilled in industrial automation and robotics.

- Less suitable for small-scale or frequently changing production: Small workshops with constantly changing designs may not fully utilize the system’s potential.

Industrial Applications

Grinding and polishing robots are widely used in industries requiring high surface quality. In automotive, machinery, and mechanical production, they handle edge rounding, vehicle body grinding, and deburring after cutting or welding. In aerospace, turbines, medical devices, and electronics, robots can process small, complex components with absolute precision and high gloss.

Additionally, robots are applied in interior finishing, art products, stainless steel, and aluminum alloys, where aesthetics and surface uniformity are critical to the final product’s value. Their ability to handle diverse materials and shapes makes grinding & polishing robots a preferred choice for modern production lines.

We hope this article provides a clear understanding of grinding & polishing robots, their operations, advantages, and limitations to guide your investment decisions. For more information or consultation, please contact PNC TECH. We are committed to providing tailored advice based on each client’s current situation and goals, and proposing solutions that best meet operational requirements.

Learn more about our services: pnctech.dichvu

📞 Hotline: (+84) 919 247 843

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn