Goods sorting robots are modern, widely adopted technologies that automate the process of classifying and transporting items to designated locations or directly to workers. This technology not only optimizes time and costs but also enhances accuracy in warehouse operations.

In this article, PNC Tech will help you gain a deeper understanding of goods sorting robots, how they work, and their impact on the future of the logistics industry.

Overview of Goods Sorting Robots

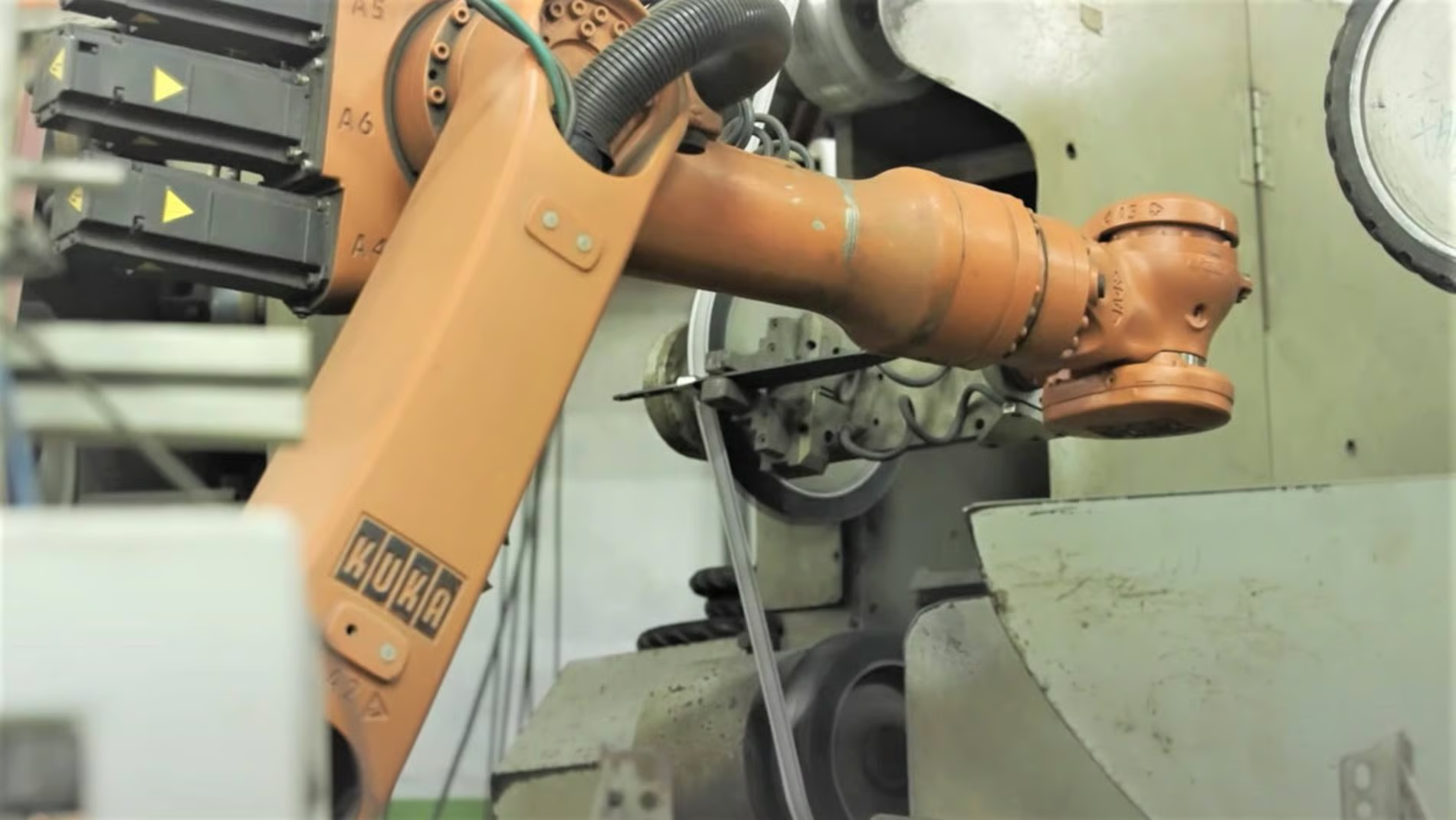

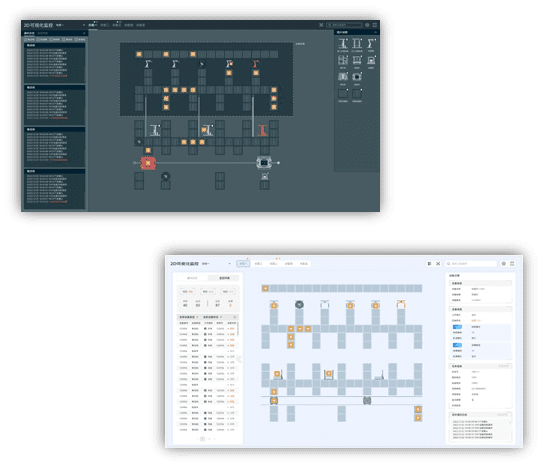

A goods sorting robot is an automated device used for classifying and organizing items in warehouses and manufacturing facilities. These robots leverage advanced technologies such as Artificial Intelligence (AI) and Machine Learning to identify, sort, and transport goods according to specific criteria, such as size, weight, barcode, or QR code.

The robots can operate independently or integrate with Warehouse Management Systems (WMS) to optimize workflow, reduce errors, and improve operational efficiency.

How Goods Sorting Robots Work

A – Transporting goods to designated locations

Goods sorting robots can deliver items to specific locations, such as storage bins or delivery bags. The process usually starts with the robot identifying the item using sensors or barcode-reading cameras, then determining the target location based on pre-programmed information. Key technologies include:

- Conveyor belts: Continuously transport items to sorting positions.

- Sensors: Help robots recognize item characteristics and adjust their movement paths.

- Barcode-reading cameras: Identify product information to ensure accurate sorting.

B – Transporting goods directly to workers (Goods-to-Person)

The “goods-to-person” model allows robots to deliver items directly to workers rather than requiring workers to move to the storage area. This not only saves time but also increases workflow flexibility. Robots can operate efficiently in complex environments, reduce labor demands, and improve overall productivity.

Organizing Items on the Robot

The arrangement of items on robots depends on factors such as size, weight, and shape. Proper sorting maximizes storage space on the robot and ensures safety during transportation. The process includes:

- Stacking by height: Items may be stacked vertically to optimize space.

- Arranging by weight: Heavier items are placed at the bottom to maintain stability.

- Grouping by size: Items with similar dimensions are grouped for easier management and transport.

(Beyond AMR technology, businesses are invited to explore related articles on the Automotive Industry developed by PNC TECH.)

Advantages & Limitations of Goods Sorting Robots

– Advantages

- Flexibility: Robots can quickly adjust to changes in production workflows or customer requirements, enhancing market adaptability.

- Energy efficiency: Robots operate continuously without breaks, saving energy compared to manual labor.

- Customizable and upgradable layouts: Robots can be reprogrammed or adjusted to accommodate new processes or warehouse layouts, providing system flexibility.

– Limitations

- Technical expertise required: Effective operation requires technicians and engineers familiar with smart traffic and robotics systems like those from PNC Tech. They understand robot operations and can design solutions tailored to each customer’s needs.

- High initial investment: The cost of acquiring and maintaining sorting robots is significant, so businesses must weigh upfront expenses against long-term benefits.

We hope this article provides a clearer understanding of goods sorting robots, their operation, advantages, and limitations before making investment decisions. For further information or consultation, contact PNC TECH for detailed support. We are committed to providing guidance tailored to the current situation and objectives of each customer and will propose solutions to best meet your operational requirements.

Learn more about our services:

📞 Hotline: (+84) 919 247 843

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn