The Role of Automation in the Green Transition

In the era of green transition and sustainable development, battery and renewable energy manufacturing plants (such as wind and solar power) play a pivotal role in the global energy supply chain. However, the industry faces the challenge of transporting and assembling bulky, heavy components such as solar modules, wind turbine blades, and battery storage systems. Manual handling in these environments not only increases costs and time but also poses significant safety risks.

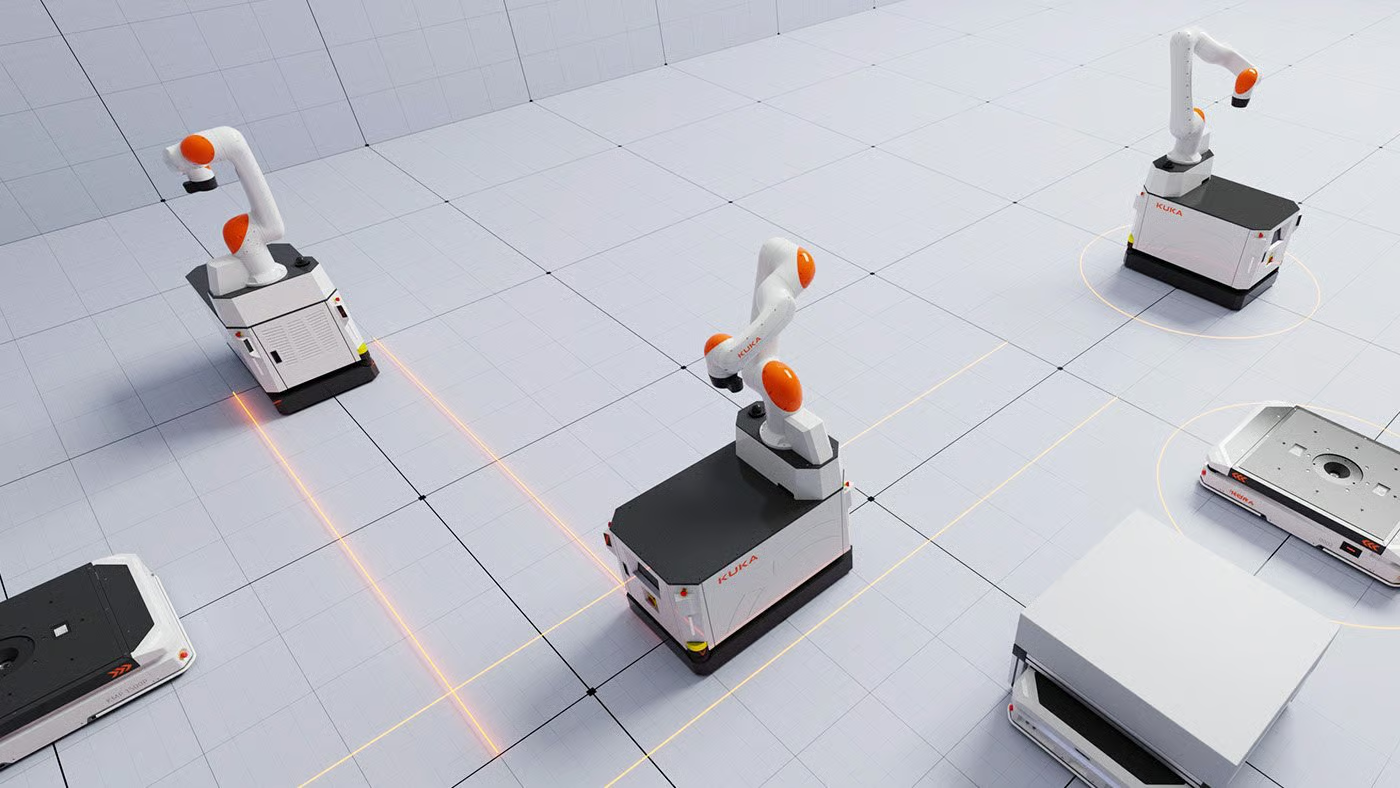

AGV (Automated Guided Vehicle) and AMR (Autonomous Mobile Robot) solutions are key technological advancements that optimize in-plant logistics, enhance operational efficiency, and minimize production risks.

Benefits of AGV/AMR in Renewable Energy Manufacturing

The deployment of AGV/AMR brings immediate, tangible benefits that significantly transform production and logistics management:

- Boost Productivity and Transport Efficiency: Robots operate continuously, automatically transporting solar modules, wind turbine blades, and heavy components, reducing reliance on manual labor.

- Ensure Safety: Equipped with advanced sensors and collision-avoidance technology, AGV/AMR operate safely even in environments crowded with workers and machinery.

- Reduce Operating Costs: Accurate and stable transportation minimizes component damage, lowers risks during storage and assembly, and reduces downtime.

- Adapt to Complex Environments: AMRs navigate flexibly within factories with complex layouts, dynamic production lines, or expansion needs.

- Enable Accurate Data Management: Integration with Warehouse Management Systems (WMS) and Manufacturing Execution Systems (MES) allows real-time data collection, predictive maintenance, and improved overall management.

Practical Applications of AGV and AMR

In practice, AGVs and AMRs serve different roles:

- AGV: Ideal for fixed routes, ensuring stable operations under pre-programmed scenarios. Commonly used to transport solar modules, pallets of raw materials, or other heavy components along designated paths.

- AMR: More flexible, equipped with SLAM (Simultaneous Localization and Mapping) for autonomous navigation. They operate effectively in dynamic environments with frequent human and equipment movement, making them suitable for wind turbine assembly areas or continuously changing production lines.

The combination of AGV and AMR allows plants to achieve both stability and flexibility, meeting the increasing demands of renewable energy production.

Industry-Specific Requirements

Battery and renewable energy production require automated transport systems that meet strict conditions:

- Heavy Load Capacity: Wind blades, solar modules, and energy storage components are extremely heavy, requiring robots with stable lifting and handling capabilities.

- High Precision: Accurate positioning and assembly ensure safety and product quality.

- Challenging Environments: Factories often have numerous obstacles and constantly changing layouts, requiring advanced collision avoidance and optimal path planning.

Technology Solutions for AGV/AMR

To meet these requirements, AGVs and AMRs in renewable energy manufacturing integrate advanced technologies:

- SLAM Technology (Simultaneous Localization and Mapping): Enables autonomous mapping, accurate localization, and optimized route planning.

- LIDAR Sensors: Function as the “eyes” of the robot, scanning 2D/3D spaces to detect obstacles and adjust paths.

- Artificial Intelligence (AI): Processes sensor data, optimizes routes based on traffic density, and supports predictive maintenance to minimize downtime.

- IoT and System Integration: Connects robots with WMS and MES for real-time coordination, monitoring, and data-driven decision-making.

These combined technologies enable AGVs and AMRs to operate reliably, precisely, and flexibly in the demanding environment of renewable energy production.

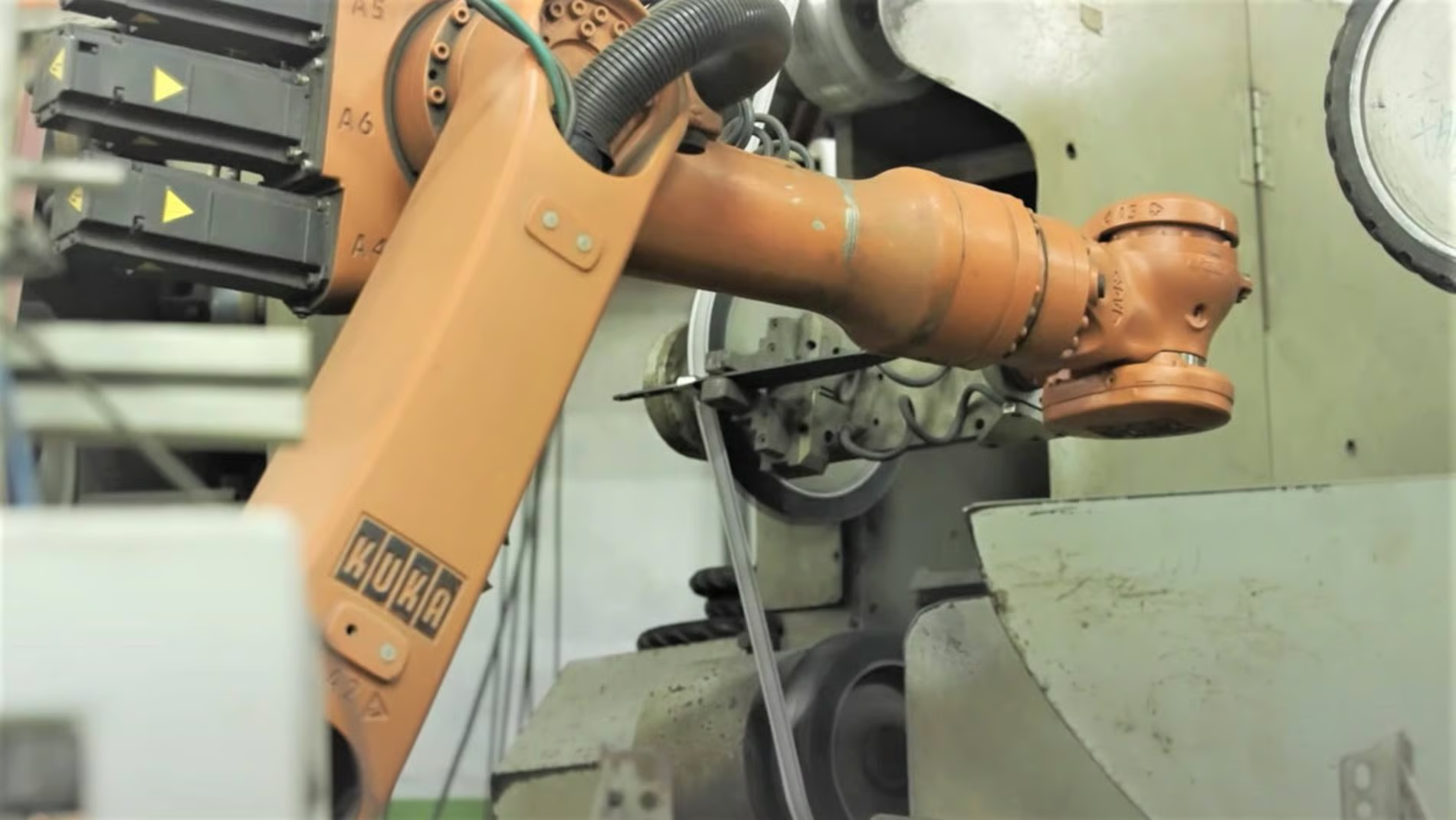

Real-World Example

In Vietnam, PNC TECH has successfully deployed AGV/AMR systems for battery and renewable energy factories. Applications include:

- Transporting solar modules and heavy components with high precision.

- Operating in wind power plants to move large blades, adapting to spatial changes and obstacles.

- Integrating SLAM, LIDAR, and AI technologies to maximize safety and efficiency.

This success paves the way for renewable energy plants in Vietnam to not only optimize production but also enhance international competitiveness.

The adoption of AGV and AMR in battery and renewable energy plants is an inevitable trend, significantly boosting production efficiency, ensuring safety, and reducing operating costs. With cutting-edge technologies such as SLAM, LIDAR, AI, and IoT, autonomous robots go beyond replacing manual labor — they drive sustainable growth and align with the future demands of the green energy sector.

Learn more about our services:

📞 Hotline: (+84) 919 247 843

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn