Autonomous Mobile Robots (AMRs) are a breakthrough solution for transporting and handling materials. With the ability to move independently, AMRs not only optimize workflows but also enhance flexibility in diverse production environments. This article will help you gain deeper insights into AMRs, their practical applications, and their impact on the industry.

Introduction to AMR

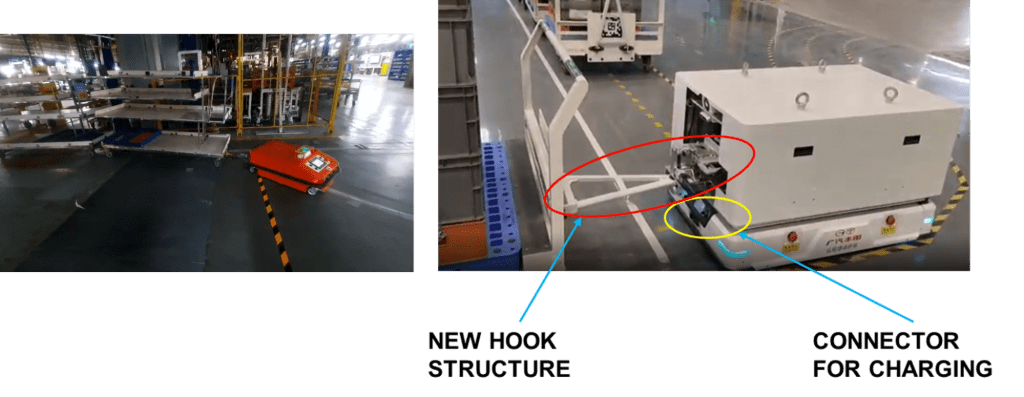

An AMR (Autonomous Mobile Robot) is a self-driving mobile robot equipped with advanced sensors and navigation systems. AMRs can self-localize and autonomously plan their routes without human intervention. The development of AMRs marks the next step beyond AGVs (Automated Guided Vehicles), which primarily operate on fixed paths. AMRs can manage high volumes of goods without collisions, ensuring intelligent traffic within factories and warehouses.

In short, an AMR is a mobile robot capable of perceiving and navigating its environment independently.

Key Differences Between AMR and AGV

| Feature | AMR | AGV |

|---|---|---|

| Navigation | AMRs can stop and reroute using sensor data. They continue operations even when facing obstacles. | AGVs cannot reroute; they stop until human intervention is provided. |

| Flexibility | Able to change routes and targets flexibly, adapting to dynamic environments. | Operates on fixed paths that are difficult to modify when environments change. |

| Collision Avoidance | Automatically finds new paths when encountering obstacles. | Stops when obstacles are detected and resumes only when cleared. |

In summary, AGVs follow predefined routes (often marked with wires or magnetic tape), whereas AMRs rely on sensors, cameras, and advanced algorithms to autonomously navigate and adapt—even in continuously changing environments.

Integrated Features of AMRs

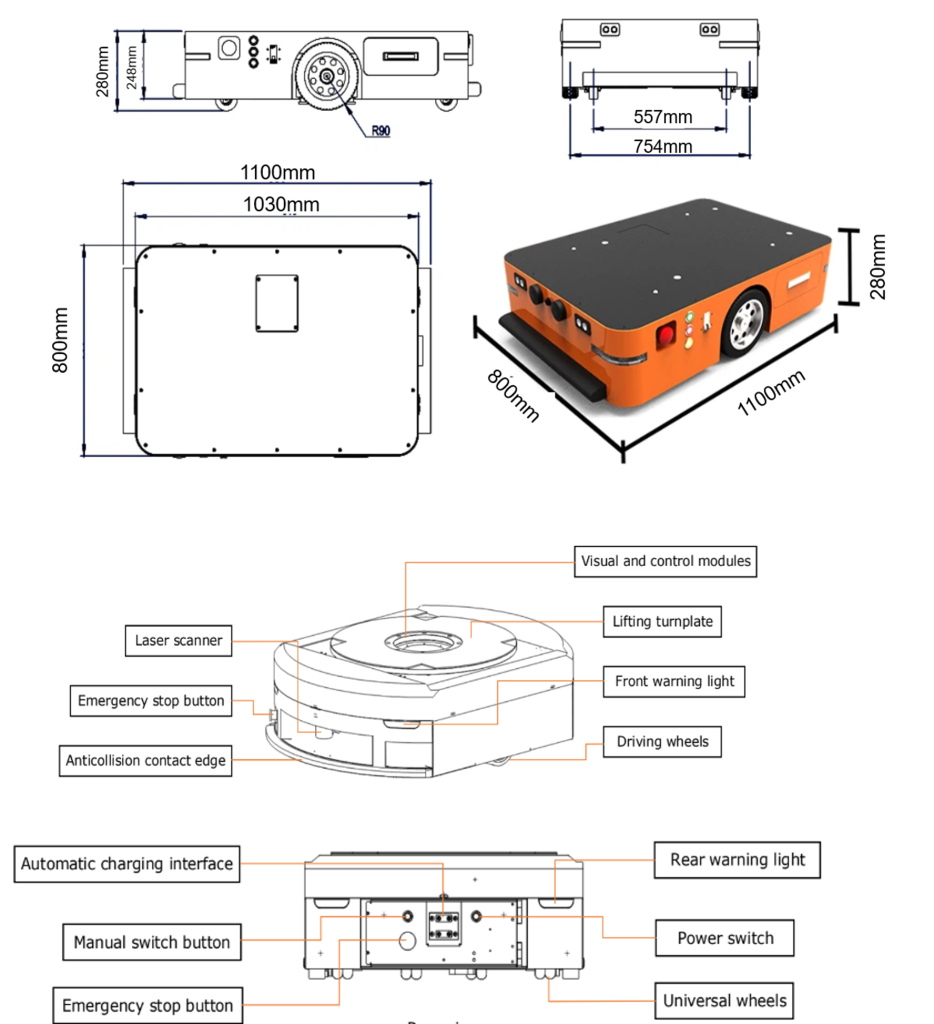

Autonomous Mobile Robots come with multiple integrated features to improve performance and ensure safety during operations:

A. Safety Sensors

- Function: Detect obstacles and humans in the working environment.

- Operation: Use ultrasonic, infrared, and laser sensors to measure distance and identify objects. Upon detection, the AMR either stops or reroutes to avoid collisions.

- Benefit: Ensures safety for both robots and humans, minimizing accident risks.

B. 3D Cameras

- Function: Provide detailed imaging of the AMR’s surrounding environment.

- Operation: Capture 3D visual and depth data to generate accurate spatial maps.

- Benefit: Enables precise object recognition, improving navigation and interaction with the environment.

C. VSLAM (Visual Simultaneous Localization and Mapping)

- Function: Allows AMRs to map the environment and determine their real-time position.

- Operation: Use cameras and image-processing algorithms to analyze surroundings and update positions on a generated map.

- Benefit: Enhances localization capability, enabling efficient operation in complex environments without human assistance.

D. Stereo Cameras

- Function: Improve environmental recognition and analysis.

- Operation: Use two or more cameras to capture multiple perspectives, creating more accurate 3D images of the surroundings.

- Benefit: Improves object detection and decision-making in complex or crowded areas.

(Beyond AMR technology, businesses are invited to explore related articles on the Automotive Industry developed by PNC TECH.)

PNC Group’s Strengths in AMR Development

- Deep industry knowledge: With extensive experience in both factories and warehouses, PNC’s development team understands the specific needs of various industries and designs AMR solutions tailored to each customer’s operations.

- Professional development team: Having participated in numerous AMR projects domestically and internationally, PNC engineers bring both technical expertise and market insights. This ensures high-quality products that meet customer demands quickly and effectively.

- Expertise in imaging and camera technology: PNC’s strengths in cameras and image processing provide a solid foundation for integrating advanced sensors into AMRs. This enhances environmental recognition and ensures safer operation.

- Comprehensive solutions: PNC not only provides AMRs but also integrates them with IoT systems, ASRS (Automated Storage and Retrieval Systems), and AGV/AMR networks.

- Customization and installation support: From hardware procurement consulting to tailored system design, PNC’s technical team assists customers in equipment selection, software configuration, and system deployment to ensure optimal performance.

- Comprehensive system management: PNC offers AMR management and maintenance services to ensure continuous, stable operations for enterprises.

With these strengths, PNC is committed to delivering advanced, efficient, and reliable AMR solutions, empowering enterprises to modernize production processes and enhance competitiveness in the era of Industry 4.0.

Contact PNC Group

If you are looking for a reliable automated warehouse solutions provider, contact PNC Group today. We will advise and deliver the most suitable automated warehouse systems tailored to your business needs and budget.

Learn more about our services: pnctech.dichvu

📞 Hotline: (+84) 919 247 843

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn