In the automotive manufacturing industry, industrial welding robots play a crucial role in the automated production and assembly lines due to their flexibility and precision.

So, what is an industrial welding robot and why does it play an important role in automotive production and manufacturing? Let’s explore the concept and advantages of this type of robot in the following article.

What is arc weld robot?

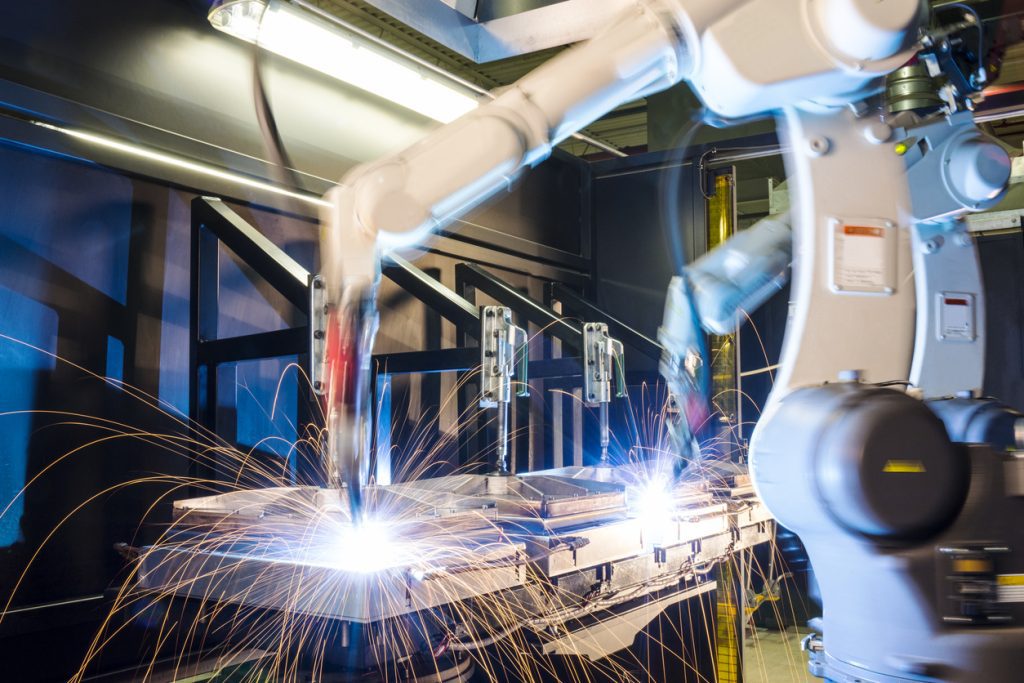

Robotic welding, also known as automated welding, is the application of pre-programmed robots to fully automate the mechanical welding process.

Depending on specific purposes, the market has introduced various types of robotic welding for mechanical machining, including MIG welding robots, wire welding robots, spot welding robots, and laser welding robots. Particularly, they are widely regarded as valuable assistants in automotive manufacturing assembly lines.

A typical welding robot has an arm-like structure with flexible rotating joints for easy movement. The welding gun is mounted at the end and can be maneuvered to weld in various positions.

The benefit of arc weld robot

Increasing production productivity

Industrial welding robots enable fast and continuous automated welding with consistent welding cycles. With their ability to operate non-stop, day and night, welding robots can help ensure a smooth, quick, and efficient production process. Welding robots can also operate in harsh conditions and replace humans in performing dangerous tasks, thereby ensuring safety for both goods and labor, and reducing risks and workplace accidents.

Improving product quality

The use of industrial welding robots helps minimize unnecessary risks to goods and avoids errors in operations. As a result, the quality of the output products is significantly improved, and the amount of waste and defects is reduced.

Cost and labor savings

Due to their precise operation, industrial welding robots contribute to reducing waste and the need for reworking products. Moreover, by replacing human labor in these tasks, businesses can save costs on hiring additional manpower.

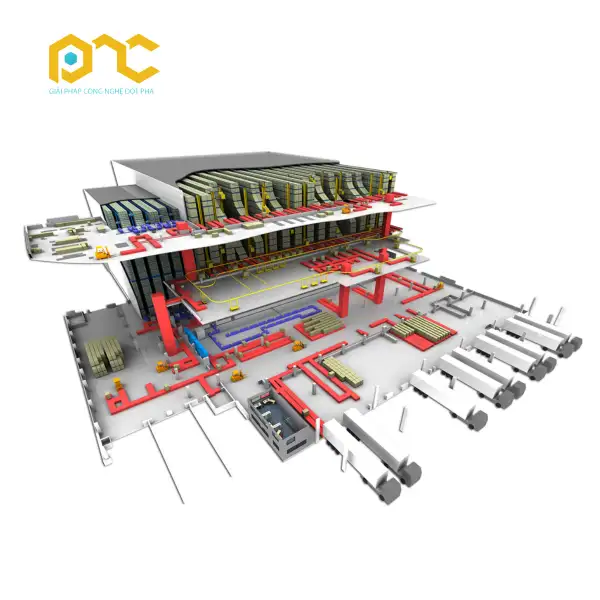

Application of arc weld robot in automotive industry

Through the article, pnctech.vn has helped readers understand that industrial welding robots are an essential part of the automated automotive production process. Various types of automated mechanical welding robots are used in the automotive manufacturing industry, in production, fabrication, and assembly lines of automated vehicles, requiring high expertise and complexity. They enable automated, precise, and fast welding processes such as spot welding, wire welding, seam welding, and laser welding.

For more detailed information about automation solutions, please visit:

Website: pnctech.vn

Hotline: (+84) 919 247 843

Email: diep.ns@pnctech.vn

Address: House A17, 17 Ta Quang Buu, Hai Ba Trung, Hanoi.