One of the crucial factors determining the quality of a product batch is the fixture. In the automotive industry, Automotive Jig – a welding fixture, is one of the complex fixtures that demands engineers with a deep understanding of the manufacturing process. So, have you found any reputable and professional companies that specialize in Jig manufacturing yet?

The development of automotive industry of Vietnam

It can be said that the Vietnamese automotive industry is still in the early stage of its development cycle. Although the market size is relatively small compared to other countries in the region, Vietnam remains a highly potential market. From an emerging and limited industry initially with the participation of Toyota, Ford, Thaco, etc., Vietnam has now become a promising market for automotive development. With favorable policies in place, the domestic automotive manufacturing sector has attracted many global car manufacturers with plans to produce in Vietnam, such as SKODA, BYD, and notably, the presence of Vinfast as a prime example of transformation in both quantity and quality (high level of automation, large-scale production complex, and annual vehicle capacity reaching hundreds of thousands). This development step has paved the way for the growth of the supporting industry. Therefore, the design of welding jigs – important auxiliary equipment in car manufacturing, will also be promoted in Vietnam.

Role of jigs in automotive manufacturing industry

In the construction of a vehicle, there are thousands of components, particularly the frame and body. Design engineers need to have a good understanding of automotive design in general and manufacturing processes (such as stamping, welding, painting, and assembly) in particular, in order to come up with suitable solutions. Welding jigs also undergo innovation and changes with the evolution of vehicle models. In general, these equipment play the following roles in car manufacturing and production:

- Jigs facilitate industrial operations by simplifying tasks, enabling repetitive and easy coordination with robots and other automated mechanisms. Additionally, in many welding technologies, jigs provide significant localized heat dissipation.

- Jigs also serve as localized heat dissipation components.

- Ensuring quality control according to the specified standards.

In addition, welding jigs also contribute to the ease of controlling and meeting the highest quality standards in production. They support the continuous operation of factory systems without interruptions, allowing for multiple shifts and efficient production schedules.

Some common types of jigs used in automotive manufacturing and production include:

Inspection Jigs: These jigs are used to measure and inspect the dimensional parameters of a product, comparing them against standards and customer requirements.

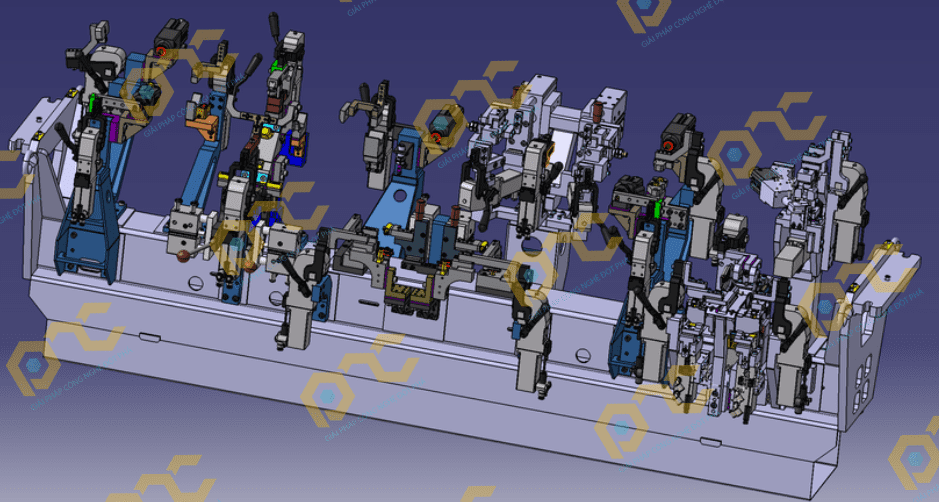

Assembly Jigs: Assembly jigs are widely used in machining and manufacturing processes. They are designed to securely hold workpieces during the assembly of components, including automotive parts. The complexity of assembly jigs varies depending on the specific product being assembled.

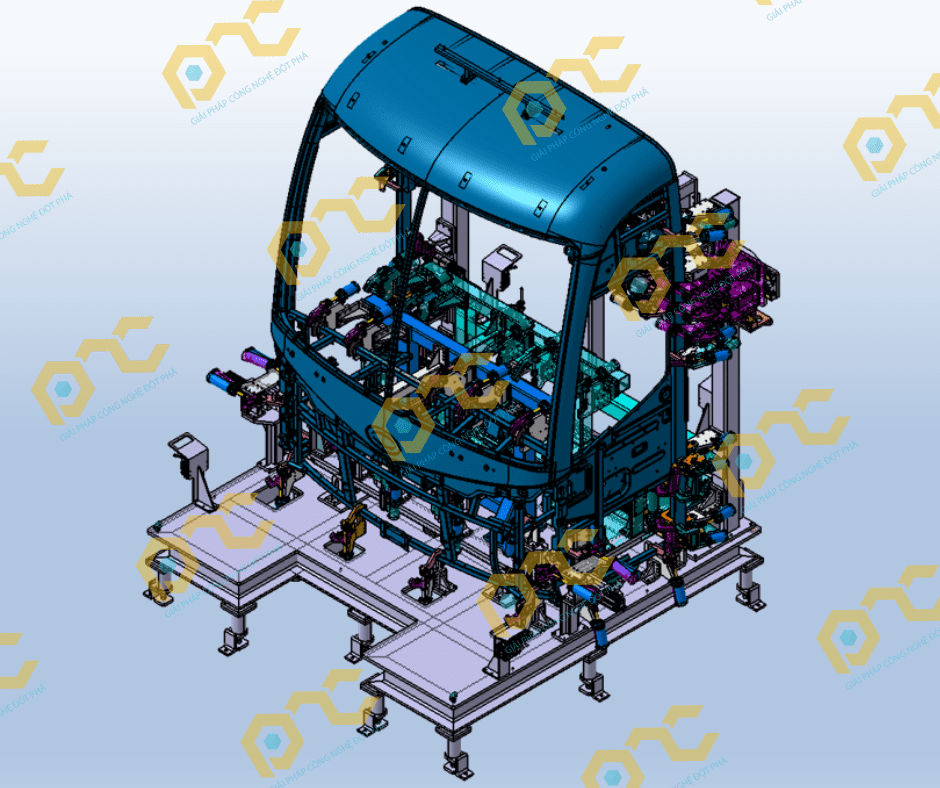

Welding Jigs: Welding jigs assist in positioning workpieces accurately in relation to welding tools, ensuring proper alignment and precise welding of automotive products.

These are just a few examples of the various types of jigs used in the automotive industry. Each type serves a specific purpose in the manufacturing and production processes, contributing to efficient and accurate assembly and quality control.

PNC’s Team

With the development of the automotive industry, including domestic brands, the presence of professional Jig welding suppliers and designers has become crucial. PNC Tech is a highly regarded name in this field, known for delivering high-quality products that support the industry’s advancements.

Despite being relatively young, PNC Tech has already gained experience in collaborating and providing complex automotive welding jigs that meet the standards of renowned brands such as Vinfast, Nissan, Toyota, and others. They have a team of highly skilled engineers with extensive experience and expertise in the automotive and automation industries. They are well-versed in the standards of different regions and manufacturers, particularly those from Asia, Europe, and America, with a deep understanding of Japanese and Korean standards. Furthermore, their engineers are proficient in English communication, enabling them to collaborate effectively with customers worldwide.

Over time, the PNC team has developed numerous high-quality Jig models and gained experience in integrating robot commissioning with Jigs, ensuring seamless operation.

PNC Tech is ready to provide consultation and solutions tailored to your needs. Feel free to contact them using the following information:

PNC TECH Automation Company Limited

Hotline: +84 919 247 843

Email: diep.ns@pnctech.vn

Address: A17 Building, 17 Ta Quang Buu, Hai Ba Trung, Hanoi.