The mechanical engineering drawing, also known as the technical drawing, is one of the crucial initial steps that significantly influences the effectiveness of the mechanical manufacturing and production process.

Why do we need to manufacture drawings?

The production process is a sequence of stages: design – simulation – ordering – machining – quality control (QC). Therefore, the design step has an impact on the outcomes of the subsequent steps.

Mechanical production is a process of transforming and shaping raw materials into a mechanical component according to the required machining drawing, using machine tools and mechanical instruments. The machining process consists of multiple small stages, each with different technical requirements. Therefore, the machining drawing is the result of research, calculation, and design stages. It serves as a guide and template for the process, ensuring the fulfillment of specified technical criteria.

By examining the standard mechanical machining drawing, the production personnel can visualize the structure, function, and operation of the component or equipment. The design drawing assists engineers in anticipating issues before machining, such as material selection, machining techniques, complexity of the component, estimation, resources, and time. Additionally, the drawing also serves as a quality control tool. Similar to the role of IT outsourcing, individuals capable of machining the drawing can perform the task remotely.

Design types can be outsourced

There are various types of mechanical designs that businesses can outsource and collaborate with professional entities to serve the production process:

Jig and fixture design: Designing jigs and fixtures involves creating fixed devices used to hold and support workpieces during machining operations. To learn more about different types of jigs and reliable jig machining providers, you can refer to this link.

Machine design: This involves designing machine versions that are modified, upgraded, or improved over time to enhance product quality and performance.

Industrial design and rapid prototyping: Design firms and businesses/customers collaborate to provide consultation and develop ideas for industrial design and rapid prototyping.

Regardless of the specific type, the machining drawing must ensure accuracy and meticulous calculation of even the smallest details. It should be created according to consistent standards and specifications. The drawing should fully depict the form, dimensions, materials used in the product, allowable tolerances, and the technical requirements set for that particular product (such as hardness, curvature, etc.). The design should comply with the regulations, standards, and criteria of technical drawing, including paper size, drawing tools, scale, symbols, and line types.

Standardized drawings facilitate an easy and efficient machining process, benefiting both the machining provider and the end-users of the product. To ensure that the product meets standards, the mechanical drawing must be accurate, aligned with the design, and meet the specified criteria.

Our’s capacity

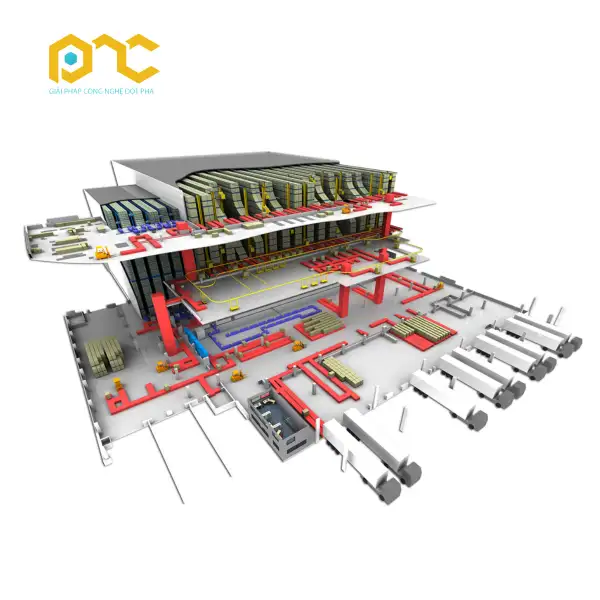

PNC Tech understands the stringent requirements of machining drawings, which is why we have developed a highly skilled and experienced team of engineers and personnel who possess in-depth knowledge of mechanical engineering, materials, and manufacturing technologies. With this expertise, we are able to collaborate with clients and efficiently execute accurate drawings.

Our engineers are proficient in both 2D and 3D design, offering flexibility for domestic projects as well as outsourcing to companies in Japan, Korea, and China. To receive detailed consultation regarding your company’s drawing machining project, please provide your information or contact us at:

PNC TECH Automation Co., Ltd.

Hotline: 0919 247 843

Email: diep.ns@pnctech.vn

Address: A17 building, 17 Ta Quang Buu, Hai Ba Trung, Hanoi.