Electric vehicles are a new revolution in the era of Industry 4.0. Recognizing this trend, PNC Tech has conducted research and development to create valuable solutions for this highly promising product.

The potential of the electric vehicle market

Did you know that in 2022, the global sales of electric vehicles were estimated at 10.6 million units, a 57% increase compared to 2021? The electric car market is expected to experience explosive growth in sales in 2023. This is undoubtedly a long-term trend as we witness global climate change, depletion of natural resources, environmental pollution, and more.

In this transition, Southeast Asia is emerging as one of the most promising markets, as manufacturers provide more options at reasonable prices to capture consumers in emerging economies. Countries in the region have advantages in terms of labor costs, electricity costs, and accumulated expertise in the automotive industry (15-20 years). This serves as an important foundation for shifting towards the electric vehicle industry with numerous advantages.

Compared to gasoline vehicles, electric vehicles also have advantages in terms of simple motor and drivetrain mechanisms, which are easy to manufacture while providing high efficiency. Therefore, strong development in the coming years is certain. The development of electric vehicles will also lead to a race in battery technology, control systems, software, and charging technologies (wireless charging, fast charging, on-the-go charging, etc.).

The potential of the electric vehicle market is both an opportunity and a challenge for equipment and solution providers in manufacturing and fabrication, such as PNC Tech.

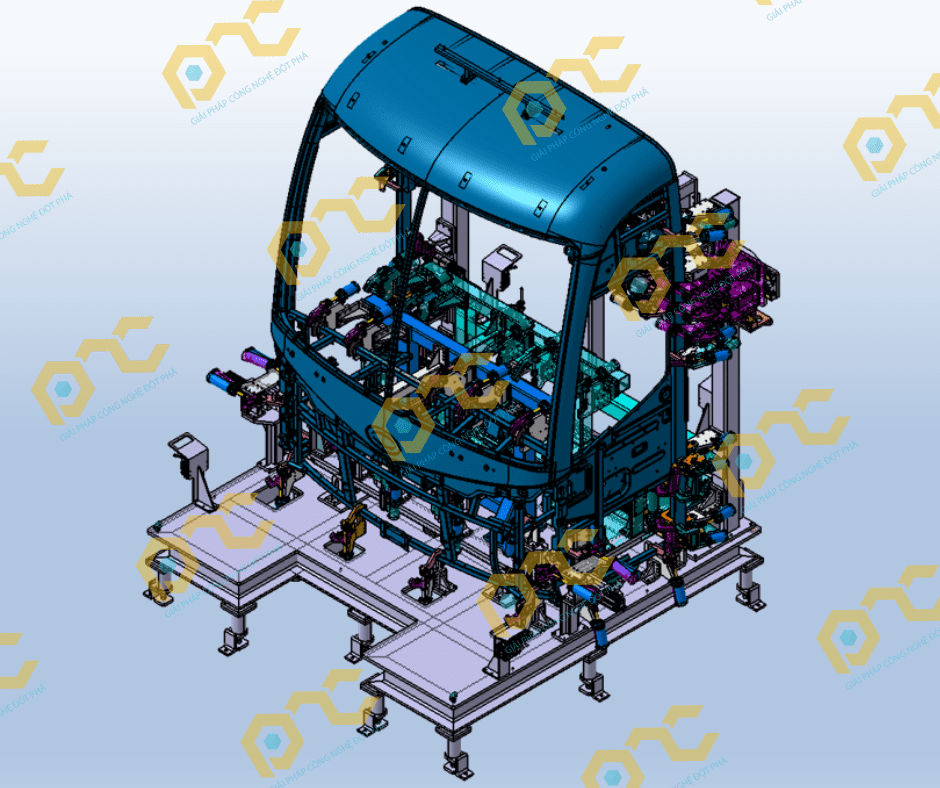

PNC Tech is at the forefront of providing design and development solutions for the electric vehicle industry. Our team of international experts, from consulting to integration, ensures that the execution team has a deep understanding and knowledge when participating in projects. This expertise enables us to develop electric vehicle prototypes according to customer requirements, whether in small or medium quantities. Additionally, PNC Tech provides support and consultation to give customers an overview of vehicle structure, materials, machinery, and related auxiliary systems before proceeding with investment and production.

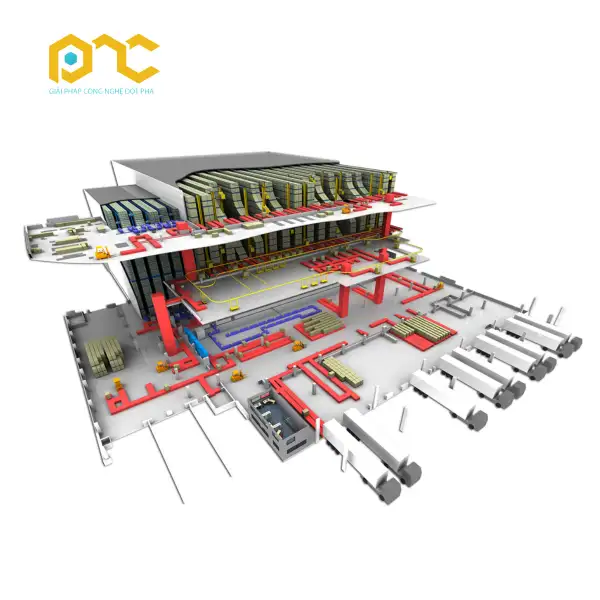

In terms of process design and machining capabilities, PNC Tech implements various stages such as blank preparation, stamping, welding, and painting, depending on the level of automation. We provide consulting services and deploy optimized machinery and production lines for customers. Moreover, PNC Tech has strong international partnerships that can supplement expert resources promptly to achieve the best results.

For electric vehicles, PNC Tech collaborates with industry-leading experts to design and program application software, display devices, and information management systems that are essential, such as mobile management, online services, information systems, and application testing.

PNC Tech has notable partners in the industry. The engineering team at PNC Tech in Vietnam possesses full capabilities in industrial design, machining processes, and component clusters for welding, testing, and assembly applications. The engineers are well-versed in Asian and European standards and have years of experience implementing projects for companies such as Toyota, Nissan, Hyundai, VinFast, and more.

In the rapidly developing automotive industry, particularly in the field of electric vehicles in Vietnam, PNC Tech continually updates and builds a highly capable team to meet the needs of customers to the best extent possible. Customers can contact us for consultations on solutions and reference specific products and projects.

Detailed information:

PNC TECH Automation Co., Ltd.

Hotline: 0919 247 843

Email: diep.ns@pnctech.vn

Address: Building A17, 17 Ta Quang Buu Street, Hai Ba Trung District, Hanoi.