The integration of Machine Vision into robots on production lines and warehouses has brought numerous benefits to businesses, with the most significant advantage being the assurance of quality and reduced dependence on human factors

Machine Vision is an essential part of the Industrial Automation field, involving the application of computer technology and optical systems to provide “vision” capabilities for machinery and robots. This enables them to recognize, analyze, and respond to information from images or image data collected from their surrounding environment.

The applications of machine vision

Faster Processing and Quick Response: Machine Vision can identify and analyze batches of image data in real-time, detecting impurities, scratches, cracks, color changes, gaps, and invisible defects that may go unnoticed by human eyes. It operates much faster and more accurately than humans and can work tirelessly 24/7. This minimizes waiting times, ensures only high-quality products are released, reduces the number of faulty products, and maintains high-quality standards for the business.

Complex Data Processing and Long-term Storage: Data collected and utilized by robots with Machine Vision can be processed in the cloud or on the edge network, allowing for scalability and detailed analysis of large and complex data. It can recognize patterns and features from images, extract crucial information, and make informed decisions. Additionally, it enables long-term storage of image data for future analysis, comparison, and performance improvement.

Operation in Harsh Environments: Machine Vision can operate in environments with low light, high or low temperatures, or other challenging conditions, reacting swiftly to hazardous situations. This helps avoid accidents and ensures safety during operations.

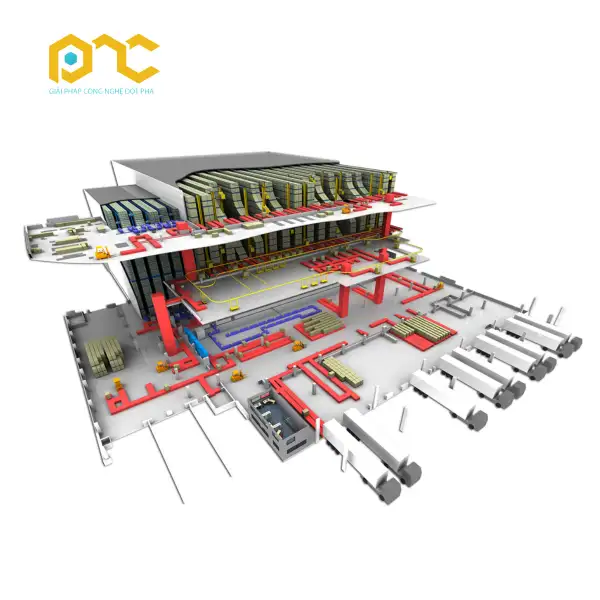

Time and Cost-saving in Transportation: With precise location positioning of goods and identifying the most optimal route, robots can quickly and accurately count, sort, and transport goods. This minimizes errors and saves time compared to manual operations, improving logistics processes and reducing transportation costs.

Optimizing Labor Costs for Businesses: Though the initial investment in this technology may be significant, in the long run, it helps businesses optimize their production and streamline control processes. For repetitive tasks influenced by environmental factors, the use of Machine Vision can reduce machine setup time and downtime, occupy less floor space, and enhance productivity.

Furthermore, Machine Vision enhances the efficiency and safety of collaboration between robots and humans. For example, in a supermarket, a robot can be dedicated to inventory management tasks, allowing humans more time to assist customers. In an assembly line, a robot with Machine Vision can analyze hazardous materials and perform dangerous tasks, eliminating the need for workers to be exposed to unsafe conditions.

In conclusion, the benefits of Machine Vision have been elucidated in this article. If you have any questions or need further consultation, please feel free to contact us:

Hotline: 0919 247 843

Email: diep.ns@pnctech.vn

Address: Building A17, 17 Ta Quang Buu, Hanoi.