Tracking raw materials plays an extremely crucial role in the efficient management and operation of both factories and warehouses. In material handling, the processes are seamlessly connected, and there is a technological transition between stages, from receiving to storage or to the production line. Everything is interconnected with appropriate technologies for effective tracking.

The inbound area is closely related to the supply processes of raw materials, which have not undergone production processing. It’s where the raw materials are transferred from input sources to intermediate distribution points such as transportation centers and processing centers.

Tracking process in inbound area

The tracking process in the inbound area involves several steps. Once the goods arrive, the Warehouse Management System (WMS) receives information about the goods, such as the type, item, quantity, and packaging style from the supplier. Based on this information, the receiving staff conduct a visual inspection of the goods and label each bundle, roll, or sheet of raw materials according to the specified packaging standards with barcode labels or RFID tags. These labels help in identifying and confirming the information about the goods accurately.

With barcode identification technology, the process involves generating barcode or QR code labels from a barcode printer. Workers then manually affix these labels onto the incoming products, enabling the seamless transition of the items through the subsequent stages.

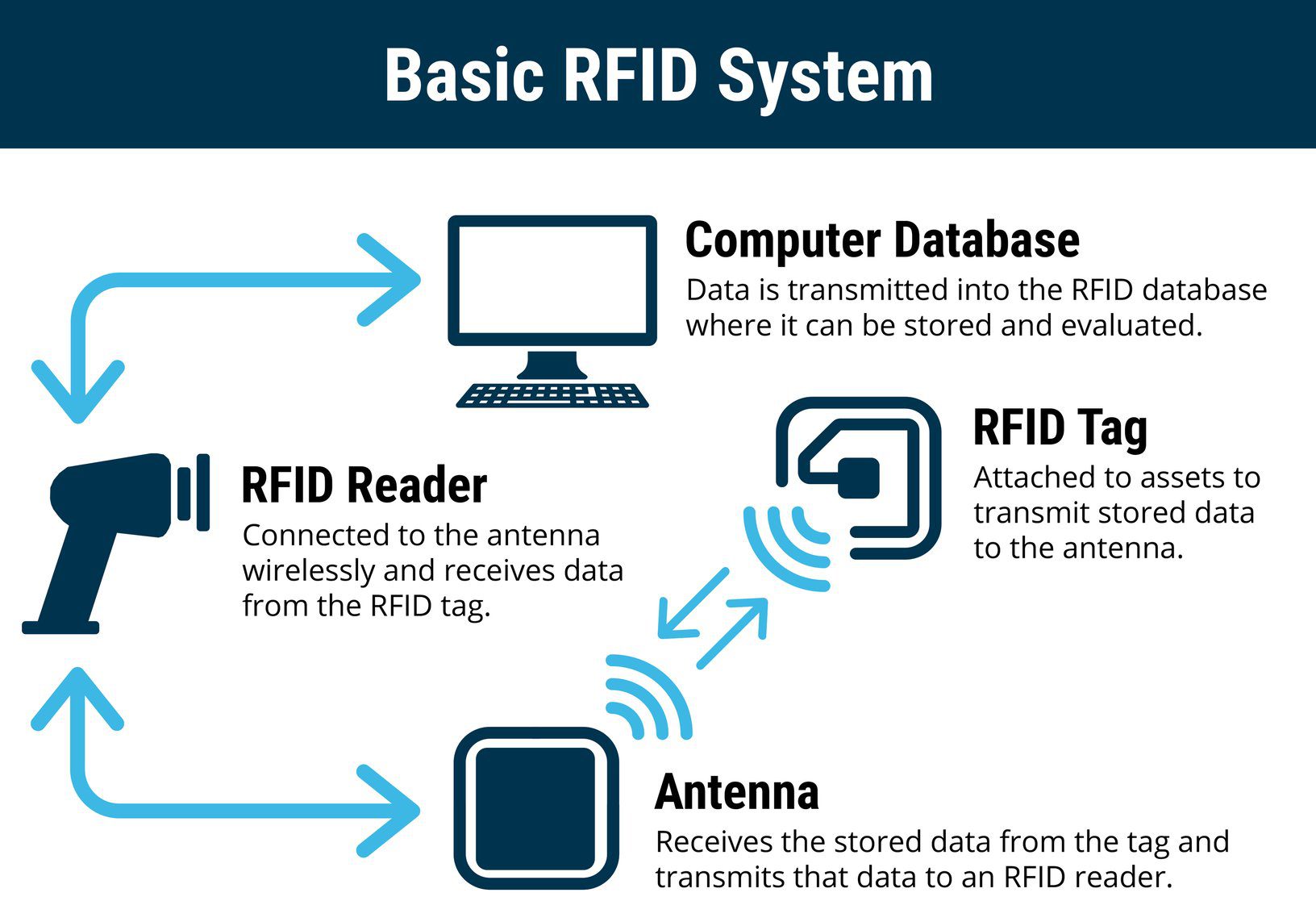

With RFID technology: RFID readers emit electromagnetic waves at a specific frequency, and RFID-tagged devices within the operating range will sense these waves and receive energy from them to transmit their tag number back to the RFID reader. At that moment, the RFID reader identifies which tags are active within the electromagnetic wave range.

Following the identification processes, employees input the supplier information into the WMS and proceed to create an inventory receipt. Based on system specifications, the system designates a storage area and provides information for the forklift operator to transport the goods to the storage area. During this stage, Automated Guided Vehicles (AGV) or Autonomous Mobile Robots (AMR) can be employed for transportation and traffic management. AGV/AMR can be pre-programmed to transport goods within the manufacturing environment, guided by magnetic strips or tracks installed on or beneath the floor. Additionally, AMR uses advanced sensors, artificial intelligence, machine learning, and computing to autonomously plan movement routes without the need for physical guides or markers. The flexibility of lidar technology enables AMR to create virtual maps and program diverse movement paths.

After the goods are transported to the storage area, employees scan the barcode of the storage location to confirm the receipt of the goods into the inventory for the WMS. Similarly, the WMS relays the information to the accounting software, completing the warehouse entry process.

Thus, PNC has established an incredibly visual and scientific solution for tracking raw materials in the inbound area with the following model:

In the subsequent stages of material handling, the tracking of raw materials continues using a combination of RFID technology, barcode systems, and pick-to-light systems. This integration is complemented by the use of AGV/AMR systems to ensure synchronization and easier management within the overall system.

PNC Tech is a reputable solution provider for material handling. They excel in providing solutions to businesses in material flow management. Understanding the logistics and transportation aspects of material flow, their autonomous mobile robot products (AGV/AMR) have helped numerous partner brands optimize their production, enhance efficiency, and save costs.

At present, PNC Tech boasts a team of highly experienced engineers with years of work experience in South Korea and Japan. They have directly collaborated with major enterprises like Viettel Post, Vinfast, Vines, Nestle, which has equipped them with valuable expertise and motivation to excel further in creativity and meet the demanding requirements of their clients.

Learn more about our services:

📞 Hotline: (+84) 964 578 906

✉️ Email: sales@pnctech.vn

🔗 Website: pnctech.vn