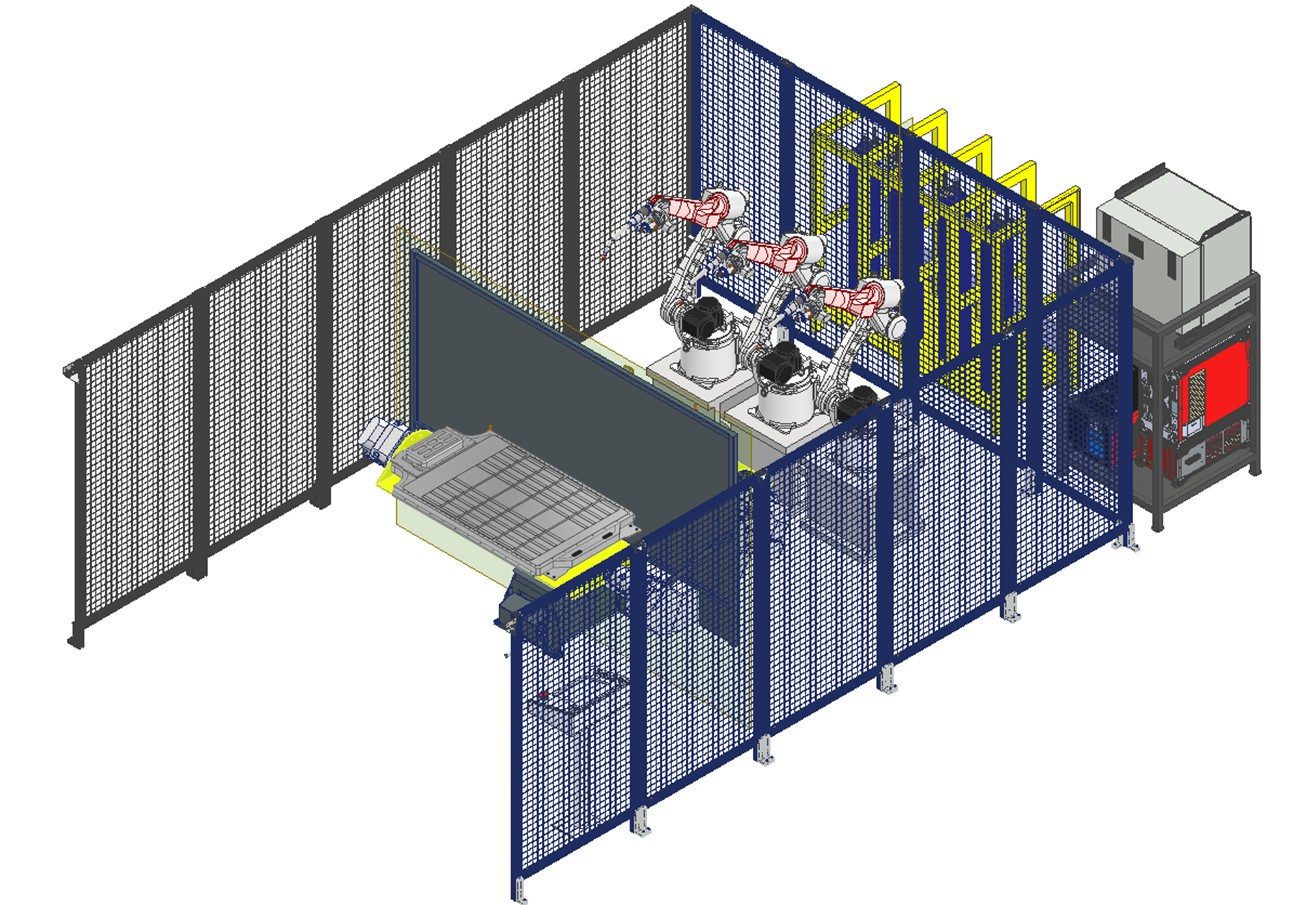

The battery housing is a crucial component of any electric vehicle – it protects the battery from potential hazards in the harsh vehicle environment and during accidents, while aiding in thermal management and acting as a protective barrier for passengers in case of battery malfunctions.

Leading battery and electric vehicle manufacturers are transitioning to laser welding for E-Mobility applications, necessitating excellent quality connections with high throughput and detailed productivity. Laser welding is a non-contact process known for its high repeatability, superior in generating low resistance and mechanically robust connections, even when joining copper and different materials.