Các giải pháp

Solutions

Nếu cần hỗ trợ, bạn có thể liên lạc với chúng tôi qua

Trung tâm hỗ trợ 24/7

(+84) 919 247 843

diep.ns@pnctech.vn

Contact us for consultation

24/7 Support Center

(+84) 919 247 843

diep.ns@pnctech.vn

Các giải pháp

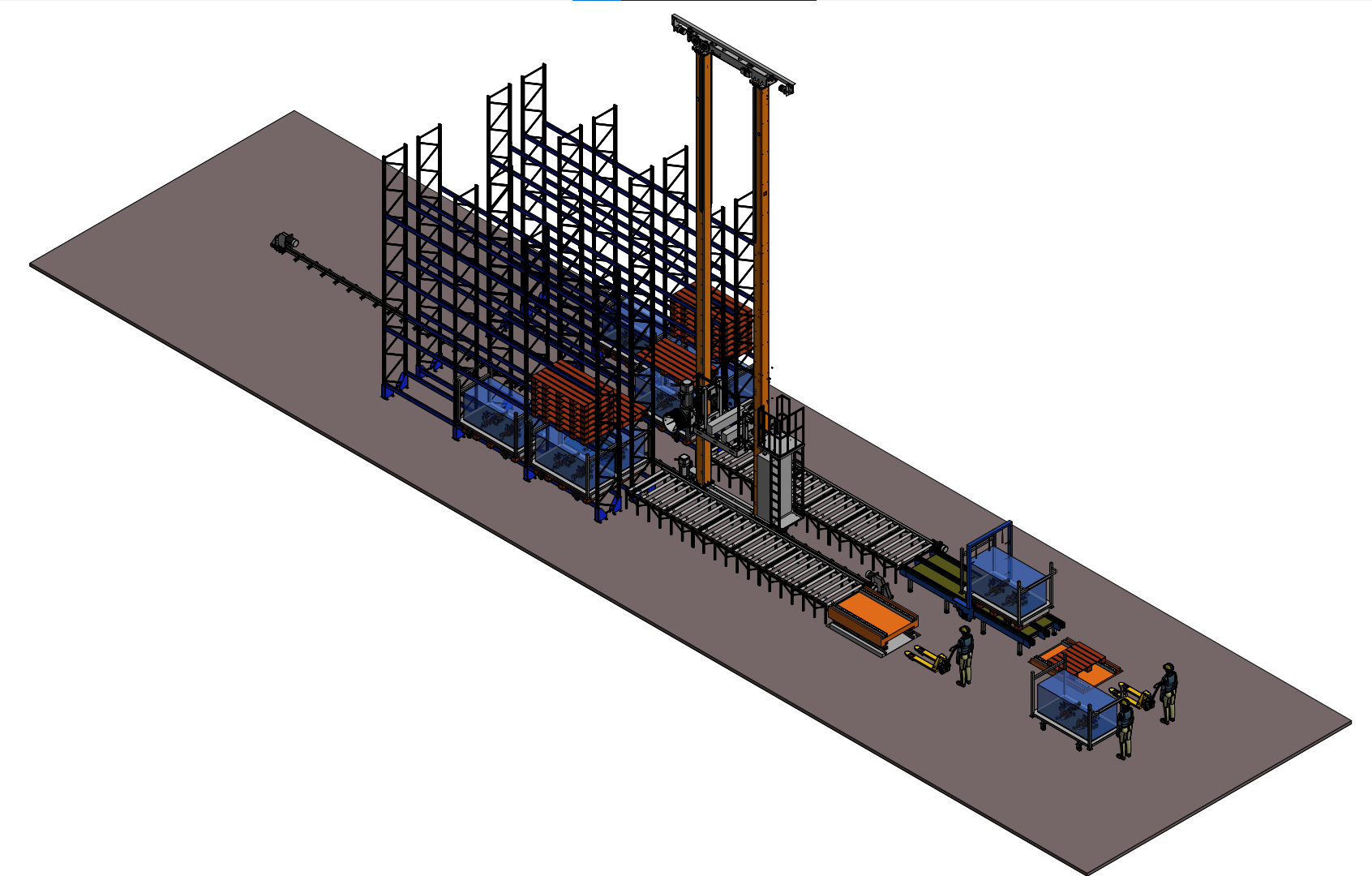

Warehouse automation ASRS

The automated storage and retrieval system (AS/RS), also known as ASRS, utilizes software, computers, and robots to streamline the handling, storage, and retrieval of items within a warehouse. These systems can be small-scale but can also be scaled up to a comprehensive network of automation that can be controlled through a suitable software solution.

ASRS leverages the combined power of various technologies and equipment to automate the retrieval and storage of large-volume loads. Moreover, they accomplish this with precision, whether it involves loading a load into a storage unit or retrieving it and transporting it elsewhere.

ASRS systems in warehouses utilize two types of technologies to operate:

– Software systems, such as Warehouse Control Systems (WCS) and Warehouse Management Systems (WMS)

– Material handling devices, such as cranes, conveyors, and Robot Shuttles

Working together, these systems help streamline scheduling, storage, and retrieval of items in the warehouse, as well as track inventory. Below are the most commonly used types of these systems:

– ASRS Unit-load – used for large loads such as crates or pallets. ASRS unit-load is used for loads typically weighing several thousand pounds. It uses fixed aisle cranes and mobile aisle cranes.

– ASRS Miniload – smaller than ASRS unit-load solutions. ASRS Miniload utilizes shuttles and cranes, making it suitable for warehouses with narrow aisles.

– Horizontal conveyors – used for sorting small pieces and components. Horizontal conveyors utilize trays and rotate them horizontally to move the goods.

– Vertical conveyors – similar to horizontal conveyors. They rotate vertically, maximizing the use of storage space.

– Vertical Lift Modules (VLMs) – automatic picking or storage units placed between storage columns. VLMs assist in picking and storing items within trays.

– Pallet Shuttle storage – a robotic shuttle system designed to operate within a cube-style storage grid.

Hình ảnh sản phẩm

Product Images

Mô tả giải pháp

Solution Description

- Diễn giải phần cứng

- Diễn giải phần mềm

- Diễn giải phụ kiện

Năng lực của chúng tôi

Our Capacity

Quy trình làm việc của PNC Tech

Tư vấn giải pháp

Triển khai và cài đặt

Bảo hành và bảo dưỡng

PNC Tech Execution Process

Consultation

Execution and Installation

Support and Warranty

Nhà cung cấp nổi bật

Standout Provider

Yêu cầu tư vấn

Consultation Request

Nếu cần hỗ trợ, bạn có thể liên lạc với chúng tôi qua

Trung tâm hỗ trợ 24/7