PNC TECH Capabilities

PNC TECH has a team of over 10 design engineers and more than 20 installation and testing personnel, aligning at the customer’s location, having experience through projects in Korea and Japan.

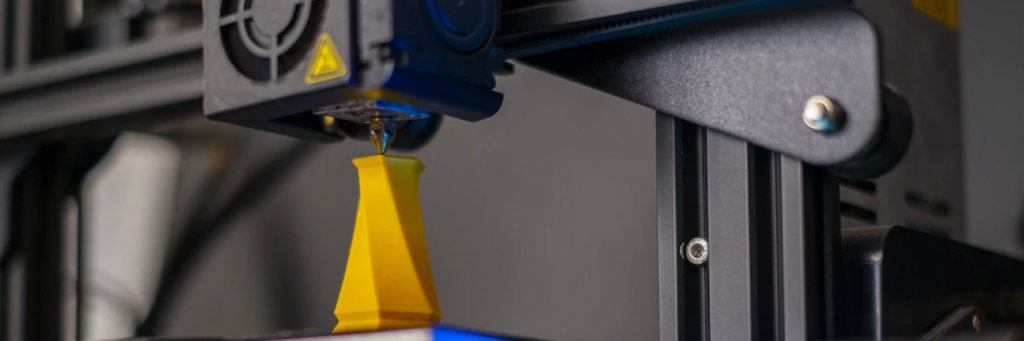

Implementation capabilities

Design and Manufacturing

- Layout of the entire Jig line. (Welding station, Robot position, Hanger, auxiliary equipment, ..)

- Calculate welding time, make a spreadsheet of welding sequence.

- Calculate and set detailed specifications for each stage (station).

- Detailed 3D design of each station. (Catia Products)

- Simulate operation of Jigs, Robots, Welding Guns.

- Avoid errors during operation.

- Using software Delmia, Robot Studio.

- Export detailed 2D drawings. (Catdrawing, Dwg)

- The processing, assembly and alignment are completed before handing over to the factory.

- Processing capacity: 10 – 20 stages/month. Depending on the nature and requirements of each project.

Machine Operation

- Seiki VK45, VK55, NR23, NK25, NR20

- Lathe 2100, Mazak 860

- Round Grinding Shigiya 1100

- Horizontal Milling ENSHU

- Multi-Function milling NIGATA

- Drill KIWA & AZUMA

- Electrical Drill & Vertical Drill

- Máy CMM

Project implementation of PNC TECH

PNC TECH has a team capable of designing 2D, 3D, flexible for projects in Vietnam and outsourcing for Japanese, Korean and Chinese companies. The team has Workshop with full tools to perform processing steps and check products before handing over to customers, both ensuring quality and saving time and costs.