With the advancement of logistics, autonomous vehicles within warehouses have become indispensable equipment, effectively addressing various issues related to costs, labor, safety, and time for many businesses.

The boom of logistics in Vietnam

Logistics is the intermediary step to deliver goods (products or services) to consumers, involving activities such as material management, import and export transportation, fleet management, warehouse operations, order fulfillment, inventory management, production planning, and packaging.

Regarding the development of logistics, according to the World Bank, Vietnam currently ranks 64th out of 160 countries globally and is the 4th in the ASEAN region, following Singapore, Malaysia, and Thailand. With an annual growth rate of around 14-16%, it is one of the fastest-growing and most stable service sectors in Vietnam in recent years.

Due to its significant growth potential, automated transportation within warehouses has become a crucial concern for businesses. This technology offers efficient solutions for cost savings, labor optimization, enhanced safety, and time management within warehouse operations. By adopting autonomous vehicles and robotic systems, businesses can increase productivity, reduce errors, and improve overall operational efficiency.

The role and applications of autonomous vehicles in warehouses

The era of Industry 4.0 demands fast and efficient services while ensuring quality and convenience for consumers. Therefore, for logistics operations, businesses have a significant need to optimize their post-processing to ensure increasingly faster deliveries.

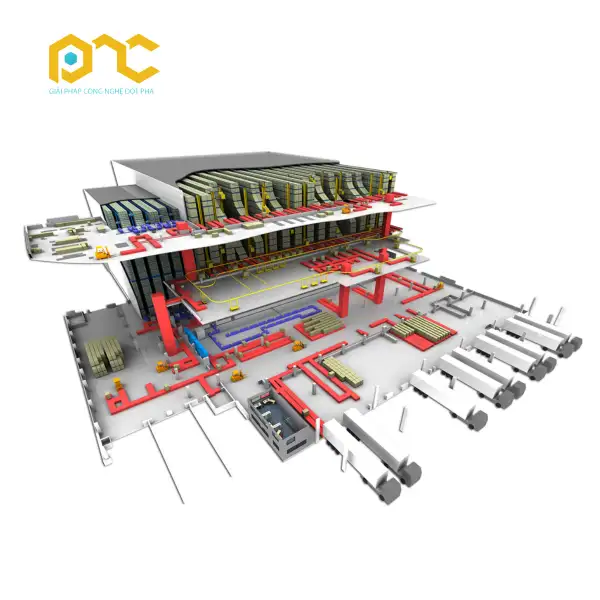

Within warehouses, various types of autonomous vehicles are primarily applied, such as sorting AGVs (Automated Guided Vehicles) and transport AGVs. There are three main applications of autonomous vehicles:

- Picking – AGV for picking: The AGV navigates to the designated storage area and retrieves the specific items based on their unique identifiers stored in the software system.

- Sorting – AGV for sorting: In the sorting area, AGVs perform the task of picking and placing items into precise designated slots based on algorithms that guide them step by step. This requires detailed and scientific calculations to achieve high performance rates, reaching thousands of pieces per hour. Multiple AGVs can be controlled simultaneously in this process.

- Transporting – AGV for transport: Once items are picked and consolidated, AGVs with larger payloads proceed to collect and transport the goods to inbound and outbound areas.

Using autonomous vehicles (AGVs) in automated warehouse transportation plays a crucial role, offering several advantages:

- Independence from human labor: With the assistance of autonomous vehicles, businesses can save significant manpower and labor costs. Moreover, by employing advanced technological solutions, the risk of workplace accidents can be substantially reduced, allowing for continuous operations 24/7.

- High productivity: With the ability to handle large volumes of goods, autonomous vehicles enhance efficiency, speed, and work quality while minimizing errors. This optimization leads to cost and time savings.

- Easy replication: Autonomous vehicles are managed through a system that ensures consistent speed and work performance among the vehicles. This synchronization enables warehouse operations to be streamlined and expedited.

When using PNC Tech’s autonomous vehicles (AGVs) in warehouses, it’s important to keep the following points in mind:

- PNC Tech’s system can support the control of hundreds of AGVs simultaneously on one floor. If there are 20 AGVs, they can be added to the control system without requiring any modification to the system software.

- To avoid collisions between multiple AGVs at intersections or restrict access to specific routes for a single AGV, the system’s traffic control feature can be utilized.

- The step-by-step control algorithm follows the “first in, first out” principle. The traffic control system monitors the real-time position of each AGV to ensure proper sequencing.

- When an AGV completes a task at a destination, the system will proactively send it to a designated waiting station, allowing the AGV to automatically return to the waiting point.

By considering these guidelines when using PNC Tech’s AGVs, customers can effectively manage the operation and coordination of multiple autonomous vehicles within their warehouse environment.

Cooperating with PNC Tech for the use of autonomous vehicles (AGVs) offers several significant benefits, including:

Experienced team: PNC Tech has a team of highly skilled experts with extensive experience in the field of automation. This ensures that their AGV products are developed and provided by individuals with deep industry knowledge and a high capability to develop advanced applications.

High efficiency: PNC Tech’s AGV scheduling system is designed to find the most optimal routes without collisions. This enhances efficiency in transportation and cargo handling operations.

High flexibility: PNC Tech’s AGVs have the ability to recognize positions and navigate flexibly, allowing them to interact and coordinate with other processing devices within warehouse environments.

Safety and reliability: AGVs from PNC Tech are designed to automatically halt before colliding with obstacles, ensuring safety for employees and warehouse assets.

Diverse positioning methods: PNC Tech’s AGVs support multiple positioning methods, such as QR code navigation, magnetic tape guidance, and laser-based SLAM navigation. This enhances precise positioning capabilities.

Automatic charging: AGVs are equipped with automatic charging capabilities, enabling them to distribute themselves to the corresponding charging stations. This ensures that the robots always have sufficient energy and prolongs battery life.

Currently, we are partnering with Viettel Post, Vinfast, Vines, Nestle, and other prominent companies. If you have a need for autonomous vehicles (AGVs) in your warehouse, please feel free to contact PNC Tech using the following information:

Company name: PNC TECH Automation Co., Ltd.

Hotline: 0919 247 843

Email: diep.ns@pnctech.vn

Address: A17 Building, 17 Ta Quang Buu, Hai Ba Trung, Hanoi.

We look forward to discussing your requirements and providing you with the best solutions for your warehouse automation needs.